| | My Small Engine Projects |  |

|

+7Double W Cross Ranch mr.modified Packman AllisKidD21 MightyRaze RichieRichOverdrive MatthewD 11 posters |

|

| Author | Message |

|---|

AllisKidD21

Moderator

2020 Build-Off Entrant

2020 Build-Off Entrant

1st Place Build-Off 2019

1st Place Build-Off Winner 2019

Join date : 2016-07-10

Posts : 5190

|  Subject: Re: My Small Engine Projects Subject: Re: My Small Engine Projects  July 8th 2018, 10:35 pm July 8th 2018, 10:35 pm | |

| Cool! I'd definitely love to see some more work on the "steamer" engine there, it's a pretty neat project. | |

|

| |

RichieRichOverdrive

Moderator

2018 Build-Off Entrant

2018 Build-Off Entrant

2024 Build-Off Entrant

2024 Build-Off Entrant

Age : 21

Join date : 2016-10-29

Points : 6580

Posts : 3615

Location : Lewisburg, KY

|  Subject: Re: My Small Engine Projects Subject: Re: My Small Engine Projects  July 8th 2018, 11:04 pm July 8th 2018, 11:04 pm | |

| I wouldn't use tire tubes, they don't perform well for long around oil or especially gas. They expand and get eaten i believe. If you're gonna use rubber, find some neoprene. It'd be better to use a carboard box or actual gasket material though. | |

|

| |

MightyRaze

Administrator

2017 Build-Off Finalist

2017 Build-Off Finalist

2018 Build-Off Top 3 Winner

2018 Build-Off Top 3 Winner

2019 Build-Off Top 3 Winner

2019 Build-Off Top 3 Winner

2021 Winner of Winners

2021 Winner of Winners

1st Place Build-Off 2022

1st Place Build-Off Winner 2022

10,000 POSTS!

10,000 POSTS!

2024 Build-Off Entrant

2024 Build-Off Entrant

Age : 49

Join date : 2016-09-06

Points : 15035

Posts : 10621

Location : Oklahoma

| |

| |

MatthewD

Veteran Member

2015 Build-Off Entrant

2015 Build-Off Entrant

2016 Build-Off Entrant

2016 Build-Off Entrant

Age : 22

Join date : 2014-11-16

Points : 5537

Posts : 1993

Location : Northern Ireland

|  Subject: Re: My Small Engine Projects Subject: Re: My Small Engine Projects  July 9th 2018, 12:10 pm July 9th 2018, 12:10 pm | |

| Thanks. I'll be sure to take some pics when I take it apart. Well seeing as the engine runs on compressed air and won't be in contact with gas or oil, rubber tube gasket should be ok. With regards to addressing the inefficiency, would I need to make the valves open less or more? | |

|

| |

MatthewD

Veteran Member

2015 Build-Off Entrant

2015 Build-Off Entrant

2016 Build-Off Entrant

2016 Build-Off Entrant

Age : 22

Join date : 2014-11-16

Points : 5537

Posts : 1993

Location : Northern Ireland

| |

| |

RichieRichOverdrive

Moderator

2018 Build-Off Entrant

2018 Build-Off Entrant

2024 Build-Off Entrant

2024 Build-Off Entrant

Age : 21

Join date : 2016-10-29

Points : 6580

Posts : 3615

Location : Lewisburg, KY

|  Subject: Re: My Small Engine Projects Subject: Re: My Small Engine Projects  July 24th 2018, 4:04 pm July 24th 2018, 4:04 pm | |

| Looks like a cool carb. You have access to a lathe dont you? You could drill it out and make some bushings to put in. | |

|

| |

MatthewD

Veteran Member

2015 Build-Off Entrant

2015 Build-Off Entrant

2016 Build-Off Entrant

2016 Build-Off Entrant

Age : 22

Join date : 2014-11-16

Points : 5537

Posts : 1993

Location : Northern Ireland

|  Subject: Re: My Small Engine Projects Subject: Re: My Small Engine Projects  July 24th 2018, 4:09 pm July 24th 2018, 4:09 pm | |

| Yeah I do. Although the shaft doesn't seem to be loose, it's more the butterfly that is loose on the shaft. I'll see if I can take the throttle butterfly and shaft out and take a look at it. | |

|

| |

Crazy_Carl

Veteran Member

2018 Build-Off Entrant

2018 Build-Off Entrant

2024 Build-Off Entrant

2024 Build-Off Entrant

Age : 35

Join date : 2017-10-30

Points : 5117

Posts : 2561

Location : Rochester, New York

| |

| |

MightyRaze

Administrator

2017 Build-Off Finalist

2017 Build-Off Finalist

2018 Build-Off Top 3 Winner

2018 Build-Off Top 3 Winner

2019 Build-Off Top 3 Winner

2019 Build-Off Top 3 Winner

2021 Winner of Winners

2021 Winner of Winners

1st Place Build-Off 2022

1st Place Build-Off Winner 2022

10,000 POSTS!

10,000 POSTS!

2024 Build-Off Entrant

2024 Build-Off Entrant

Age : 49

Join date : 2016-09-06

Points : 15035

Posts : 10621

Location : Oklahoma

|  Subject: Re: My Small Engine Projects Subject: Re: My Small Engine Projects  July 24th 2018, 6:50 pm July 24th 2018, 6:50 pm | |

| That is what I was hoping. These engines are sure neat you got going on. I'm waiting for the day you power a mower with a steam engine! | |

|

| |

Double W Cross Ranch

Veteran Member

2018 Build-Off Finalist

2018 Build-Off Finalist

Age : 20

Join date : 2017-06-09

Points : 5276

Posts : 2640

Location : Literally Nowhere, Texas

| |

| |

MatthewD

Veteran Member

2015 Build-Off Entrant

2015 Build-Off Entrant

2016 Build-Off Entrant

2016 Build-Off Entrant

Age : 22

Join date : 2014-11-16

Points : 5537

Posts : 1993

Location : Northern Ireland

|  Subject: Re: My Small Engine Projects Subject: Re: My Small Engine Projects  July 25th 2018, 2:16 pm July 25th 2018, 2:16 pm | |

| - Crazy_Carl wrote:

- Hopfully the screws holding on the butterfly are just loose.

Yep, that's the hope. - MightyRaze wrote:

- That is what I was hoping. These engines are sure neat you got going on. I'm waiting for the day you power a mower with a steam engine!

Thanks! The biggest problem with a steam engine is the boiler, would probably need to tow a trailer with it on. - Double W Cross Ranch wrote:

- Sweet man!

Thanks W. | |

|

| |

MatthewD

Veteran Member

2015 Build-Off Entrant

2015 Build-Off Entrant

2016 Build-Off Entrant

2016 Build-Off Entrant

Age : 22

Join date : 2014-11-16

Points : 5537

Posts : 1993

Location : Northern Ireland

| |

| |

AllisKidD21

Moderator

2020 Build-Off Entrant

2020 Build-Off Entrant

1st Place Build-Off 2019

1st Place Build-Off Winner 2019

Age : 25

Join date : 2016-07-10

Points : 8371

Posts : 5190

Location : Ontario Canada

|  Subject: Re: My Small Engine Projects Subject: Re: My Small Engine Projects  July 30th 2018, 5:47 pm July 30th 2018, 5:47 pm | |

| That's a pretty neat little engine. I've don't think I've seen one of the updraft carbs on a small Briggs like that, usually the diaphragm ones like you mentioned. Also yeah I'd see if you can take the valve right out and clean up the stem with a wire wheel or something. Hopefully it's not rusted bad enough that it won't come out.  "This'll either wake you up or put you to sleep forever!"- Red Green "Whatever you do you should do right, even if it's something wrong." - Hank Hill - MTD Off-Road Build

- Ford LT 110 Off-Road Build

- Craftsman GT 6000 Off-Road Build

- Sears LT11 Rat Rod Build *2019 Build-Off Winner!* Garden Tractor Collection: Allis B-110 x2, 710, 716, & 410 - Wheel Horse 655, 953 & 500 Special - Case 444 - Bolens Versamatic, G10 & 1668 Diesel Swapped - Cub 106, 124 & 1000/149 Frankentractor - Ford 120, LGT 125 & 145 - White 1650 Yard Boss - Moto Mower 710-100 | |

|

| |

Crazy_Carl

Veteran Member

2018 Build-Off Entrant

2018 Build-Off Entrant

2024 Build-Off Entrant

2024 Build-Off Entrant

Age : 35

Join date : 2017-10-30

Points : 5117

Posts : 2561

Location : Rochester, New York

|  Subject: Re: My Small Engine Projects Subject: Re: My Small Engine Projects  July 30th 2018, 7:22 pm July 30th 2018, 7:22 pm | |

| Defintely a prime candidate for a CDI conversion.

DO you have any use for a pump like that? | |

|

| |

prancstaman

Veteran Member

Join date : 2015-02-02

Points : 4880

Posts : 1412

Location : Cleveland,Ohio

|  Subject: Re: My Small Engine Projects Subject: Re: My Small Engine Projects  July 30th 2018, 9:50 pm July 30th 2018, 9:50 pm | |

| For the air motor/steam motor, on the camshaft lobes for it to be efficient- You want the cam lobes to open the corresponding valves right at top dead center and at bottom dead center. They are not like regular engines where you have valve overlap. The valve overlap will rob the engine of power and efficiency. When the 2 valves are open on the overlap the air blows by the piston and goes right out the exhaust which creates a domino effect. More air or steam is used at lower rpm then at higher rpm but since you are loosing air then that means the motor is weaker.

The idea you are shooting for is- when the intake valve opens, the exhaust will be closed for no air loss, the incoming air fills the cylinder while pushing the piston to expand the cylinder. At the bottom of the crankshaft throw, when the piston reaches bottom dead center then the intake valve is completely closed and the exhaust valve is just starting to open to dump the pressure, then the piston moves up from momentum and exhausts the air, and at top dead center the exhaust valve is completely closed and the intake is just starting to open while the momentum of the crank pushes over top dead center of the piston to restart the cycles. And having the valves open late meaning the piston is past top dead center or bottom dead center, then the motor would be fighting itself to move also.

When you start thinking about the motor how I described it then you will see what will rob the motor power and what will add power and efficiency. For example, the momentum part would mean the motor would have an idle rpm to carry through to the next power stroke from the previous power stroke. And how the valve overlap from the gas motor camshaft will rob power by the air/steam bypassing the piston at top dead center and bottom dead center. | |

|

| |

Crazy_Carl

Veteran Member

2018 Build-Off Entrant

2018 Build-Off Entrant

2024 Build-Off Entrant

2024 Build-Off Entrant

Age : 35

Join date : 2017-10-30

Points : 5117

Posts : 2561

Location : Rochester, New York

|  Subject: Re: My Small Engine Projects Subject: Re: My Small Engine Projects  July 31st 2018, 10:31 am July 31st 2018, 10:31 am | |

| If you were trying to get the engine going on steam and the valves were in that position where each was open just a little I don't think it would start at all or efficiently. | |

|

| |

MatthewD

Veteran Member

2015 Build-Off Entrant

2015 Build-Off Entrant

2016 Build-Off Entrant

2016 Build-Off Entrant

Age : 22

Join date : 2014-11-16

Points : 5537

Posts : 1993

Location : Northern Ireland

|  Subject: Re: My Small Engine Projects Subject: Re: My Small Engine Projects  July 31st 2018, 6:51 pm July 31st 2018, 6:51 pm | |

| - AllisKidD21 wrote:

- That's a pretty neat little engine. I've don't think I've seen one of the updraft carbs on a small Briggs like that, usually the diaphragm ones like you mentioned. Also yeah I'd see if you can take the valve right out and clean up the stem with a wire wheel or something. Hopefully it's not rusted bad enough that it won't come out.

Thanks. The updraft carbs are normally used on the bigger Briggs', 8hp and up. I'm also going to lap the valves after I get the exhaust valve unstuck. I'll clean the valve stem with sand paper or something. - Crazy_Carl wrote:

- Defintely a prime candidate for a CDI conversion.

DO you have any use for a pump like that? What do you mean by CDI? I don't really, but I might be able to find something for it to do. - prancstaman wrote:

- For the air motor/steam motor, on the camshaft lobes for it to be efficient- You want the cam lobes to open the corresponding valves right at top dead center and at bottom dead center. They are not like regular engines where you have valve overlap. The valve overlap will rob the engine of power and efficiency. When the 2 valves are open on the overlap the air blows by the piston and goes right out the exhaust which creates a domino effect. More air or steam is used at lower rpm then at higher rpm but since you are loosing air then that means the motor is weaker.

The idea you are shooting for is- when the intake valve opens, the exhaust will be closed for no air loss, the incoming air fills the cylinder while pushing the piston to expand the cylinder. At the bottom of the crankshaft throw, when the piston reaches bottom dead center then the intake valve is completely closed and the exhaust valve is just starting to open to dump the pressure, then the piston moves up from momentum and exhausts the air, and at top dead center the exhaust valve is completely closed and the intake is just starting to open while the momentum of the crank pushes over top dead center of the piston to restart the cycles. And having the valves open late meaning the piston is past top dead center or bottom dead center, then the motor would be fighting itself to move also.

When you start thinking about the motor how I described it then you will see what will rob the motor power and what will add power and efficiency. For example, the momentum part would mean the motor would have an idle rpm to carry through to the next power stroke from the previous power stroke. And how the valve overlap from the gas motor camshaft will rob power by the air/steam bypassing the piston at top dead center and bottom dead center. Thank you very much for the information. I plan on taking the air engine apart this weekend and adjust cam lobes. Unfortunately the design of this engine means you can't pull the cam in and out quickly to check how the valves are opening and closing like on most small engines, but I should be able to manage. - Crazy_Carl wrote:

- If you were trying to get the engine going on steam and the valves were in that position where each was open just a little I don't think it would start at all or efficiently.

To start it you need to have both valves closed. Then plug the air/steam in and away it goes. On one stroke both valves are closed at the same time, but on the other the intake is opening before the exhaust is closed so I think that's where I'm loosing power. | |

|

| |

Crazy_Carl

Veteran Member

2018 Build-Off Entrant

2018 Build-Off Entrant

2024 Build-Off Entrant

2024 Build-Off Entrant

Age : 35

Join date : 2017-10-30

Points : 5117

Posts : 2561

Location : Rochester, New York

| |

| |

MatthewD

Veteran Member

2015 Build-Off Entrant

2015 Build-Off Entrant

2016 Build-Off Entrant

2016 Build-Off Entrant

Age : 22

Join date : 2014-11-16

Points : 5537

Posts : 1993

Location : Northern Ireland

|  Subject: Re: My Small Engine Projects Subject: Re: My Small Engine Projects  July 31st 2018, 7:09 pm July 31st 2018, 7:09 pm | |

| Ah yeah, that's what I plan on doing. I'm going to cut the wire going from the coil to points, and install an electronic coil I have laying around. Hopefully I'll get spark. I can always join the wire back up again once I find a deep socket to take the flywheel nut off and get the points cleaned out but for now it's electronic ignition. I got the socket off that I got stuck on the flywheel nut trying to get it off.  | |

|

| |

prancstaman

Veteran Member

Join date : 2015-02-02

Points : 4880

Posts : 1412

Location : Cleveland,Ohio

|  Subject: Re: My Small Engine Projects Subject: Re: My Small Engine Projects  July 31st 2018, 8:06 pm July 31st 2018, 8:06 pm | |

| I see how you are doing it, with the air/steam motor. Yah, not vary efficient using the original cam because of the power stroke creating drag. Need to mod the cam to change it from a 4 cycle to a 2 cycle cam. I seen people welding lobes on the cam but always looked lumpy and not so good. Maybe try drilling and tapping holes for those fillips head screws that are button shaped to make a cam lobe. Would probably need a couple screws per lobe. Not looking for high lift but just enough to open the valve would do it. If you know what I mean.  | |

|

| |

MatthewD

Veteran Member

2015 Build-Off Entrant

2015 Build-Off Entrant

2016 Build-Off Entrant

2016 Build-Off Entrant

Age : 22

Join date : 2014-11-16

Points : 5537

Posts : 1993

Location : Northern Ireland

|  Subject: Re: My Small Engine Projects Subject: Re: My Small Engine Projects  August 1st 2018, 3:34 pm August 1st 2018, 3:34 pm | |

| I have modified the cam by welding too extra lobes on it. Otherwise it wouldn't run on compressed air, it only turned over once or twice then stopped without modding the cam. I need to take it out and weld/grind the lobes to make them open/close the valves properly. The screw idea is cool, but would be hard to adjust to get the valve opening and closing at the right time. So I cut the wire from the coil to the condensor, allowing for an electronic coil to be fitted.  Had an electronic coil from a 3.5hp Briggs. Put it on and set the gap and we have spark. Next thing to do is to get the valve unstuck and lapped.  | |

|

| |

MatthewD

Veteran Member

2015 Build-Off Entrant

2015 Build-Off Entrant

2016 Build-Off Entrant

2016 Build-Off Entrant

Age : 22

Join date : 2014-11-16

Points : 5537

Posts : 1993

Location : Northern Ireland

| |

| |

Crazy_Carl

Veteran Member

2018 Build-Off Entrant

2018 Build-Off Entrant

2024 Build-Off Entrant

2024 Build-Off Entrant

Age : 35

Join date : 2017-10-30

Points : 5117

Posts : 2561

Location : Rochester, New York

|  Subject: Re: My Small Engine Projects Subject: Re: My Small Engine Projects  August 2nd 2018, 10:48 pm August 2nd 2018, 10:48 pm | |

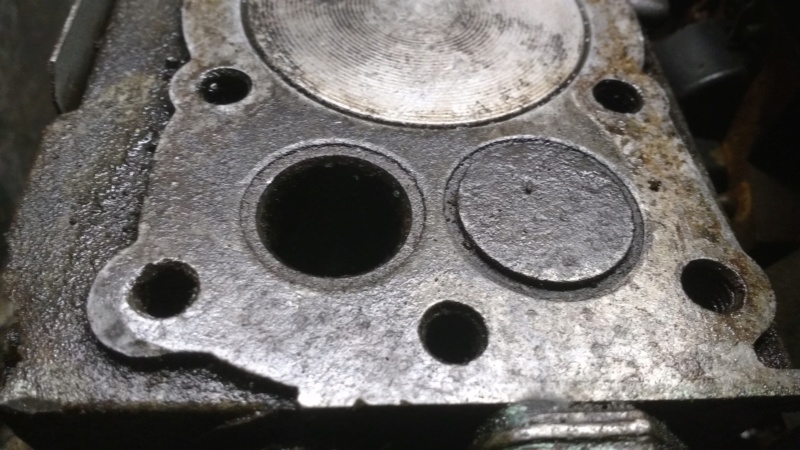

| That valve was in rough shape. Looks like it needs to see a valve grinding machine | |

|

| |

MatthewD

Veteran Member

2015 Build-Off Entrant

2015 Build-Off Entrant

2016 Build-Off Entrant

2016 Build-Off Entrant

Age : 22

Join date : 2014-11-16

Points : 5537

Posts : 1993

Location : Northern Ireland

|  Subject: Re: My Small Engine Projects Subject: Re: My Small Engine Projects  August 4th 2018, 8:57 pm August 4th 2018, 8:57 pm | |

| Yeah I did grind the valve but it's still not perfect. Got the valve in  Assembled the head, put the carb and governor system back on. Also bolted the water pump back on.  Pretty neat throttle setup, you adjust the knob by threading it up and down the rod and lock it in to hold the engine at what rpm you want.   Leak testing the fuel tank   Sanded where the holes were, any ideas on how to patch them up? I was thinking of trying to solder them, or use JB weld. I don't think welding them would work, because the steel is so thin and rusty.  Cap isn't that great either, but it sort of threads on and stays on so it should be fine.  Using the tank out of the Westwood I got it to run, after a lot of pulls. Burns quite a lot of oil, so I'm thinking the rings are bad. It still has the oil it came with though so I will change it and see what difference it makes.  Removed the Honda engine and pump from the pressure washer I got because it was leaking so much oil onto the floor, and to use the frame for the Briggs and water pump. Frame was pretty oily and dirty so I had to clean it up.  I think there should be feet or something here to keep the back of the frame up a bit but they're gone so I'm going to make something up so the engine sits level.  Test fitting the engine and pump.  Briggs and pump bolted down. Runs a lot smoother on the frame compared to running it on the floor. Handle works well to hold the temporary fuel tank.  | |

|

| |

AllisKidD21

Moderator

2020 Build-Off Entrant

2020 Build-Off Entrant

1st Place Build-Off 2019

1st Place Build-Off Winner 2019

Age : 25

Join date : 2016-07-10

Points : 8371

Posts : 5190

Location : Ontario Canada

|  Subject: Re: My Small Engine Projects Subject: Re: My Small Engine Projects  August 4th 2018, 10:44 pm August 4th 2018, 10:44 pm | |

| Nice work Matt! Soldering the holes in the tank would probably work I would think, be easier than welding it. Also about the oil burning maybe the rings just need to be freed up a bit since the engine sat so long. They might seat better after running for a while. I suppose there's a chance they could just be no good.   "This'll either wake you up or put you to sleep forever!"- Red Green "Whatever you do you should do right, even if it's something wrong." - Hank Hill - MTD Off-Road Build

- Ford LT 110 Off-Road Build

- Craftsman GT 6000 Off-Road Build

- Sears LT11 Rat Rod Build *2019 Build-Off Winner!* Garden Tractor Collection: Allis B-110 x2, 710, 716, & 410 - Wheel Horse 655, 953 & 500 Special - Case 444 - Bolens Versamatic, G10 & 1668 Diesel Swapped - Cub 106, 124 & 1000/149 Frankentractor - Ford 120, LGT 125 & 145 - White 1650 Yard Boss - Moto Mower 710-100 | |

|

| |

MatthewD

Veteran Member

2015 Build-Off Entrant

2015 Build-Off Entrant

2016 Build-Off Entrant

2016 Build-Off Entrant

Age : 22

Join date : 2014-11-16

Points : 5537

Posts : 1993

Location : Northern Ireland

|  Subject: Re: My Small Engine Projects Subject: Re: My Small Engine Projects  August 5th 2018, 1:37 pm August 5th 2018, 1:37 pm | |

| Thanks! I did try to solder up some of the holes in the tank, but only one stopped leaking. It takes quite a while to do but I think it will work if I go over them again. Yeah the rings could be seized, when the engine is cold there is reasonable compression but when it's been running for a while there isn't very much compression. | |

|

| |

Sponsored content

| |

| |

| | My Small Engine Projects |  |

|