| | “Beast” - Craftsman II Utility Build |  |

|

+10RichieRichOverdrive MightyRaze AllisKidD21 redzz02 Crazy_Carl Rerun Murraymountain CraftsmanQuad19 TheCollector WayneTrain2000 14 posters |

|

| Author | Message |

|---|

WayneTrain2000

Member

Age : 22

Join date : 2019-11-16

Points : 1903

Posts : 80

Location : Augusta, GA

|  Subject: “Beast” - Craftsman II Utility Build Subject: “Beast” - Craftsman II Utility Build  December 15th 2019, 9:14 pm December 15th 2019, 9:14 pm | |

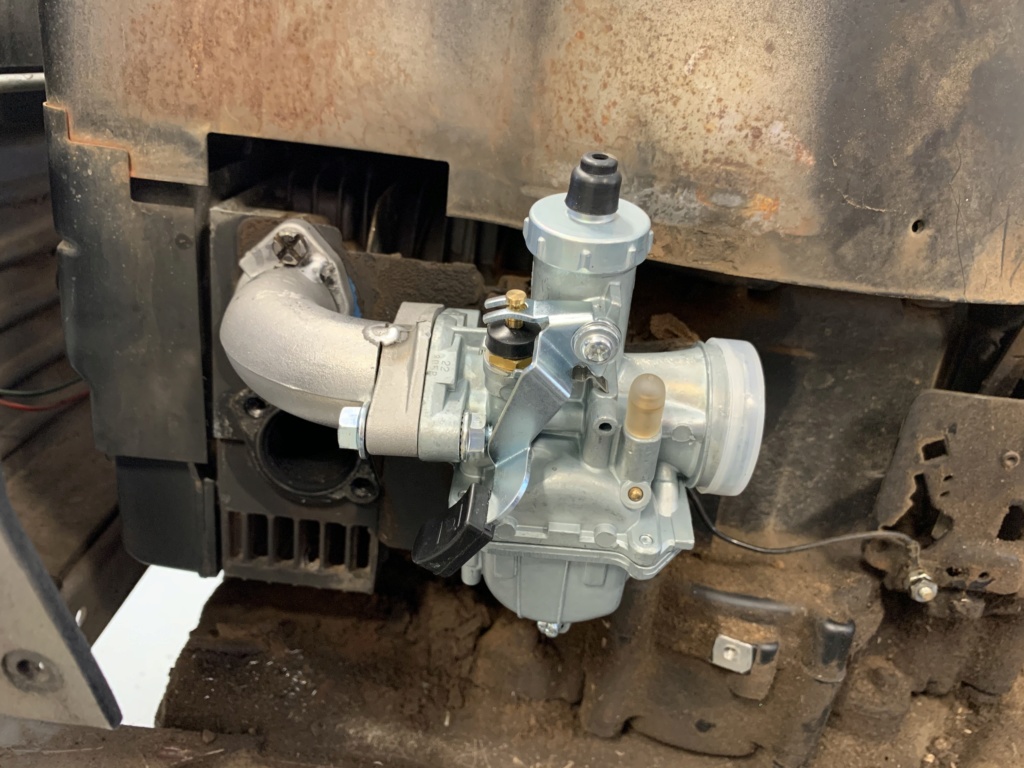

| Hi all, This is the beginning of the thread for my newest project, a (1990-92?) Craftsman II, 40” deck, 12hp flathead. We got this beauty from a buddy of mine. It was given to him, and he didn’t want anything to do with it. It had been sitting up under a shed at a hunting club for a while, so on Dec 6 we made the drive to load it up and bring it to it’s new home. The name “Beast” originated from my buddy that previously owned it, and I’d say the name fits it well. On the key, a label is stuck to it reading “BEAST”. So we’re sticking with it. Got it off the truck, charged battery, and with a shot of starting fluid she fired up. The condition of the engine was a little concerning, as it had NO oil on the dipstick, and no air filter or housing when we got it, and apparently never did during my friend’s ownership of it. Added some oil to it (it turned black immediately when the engine was run) and the engine ran really nicely. It had a SUPER low idle, at which it just sat there and purred. I believe it would run at that idle forever if you kept it fueled. Seemed to run pretty rich, as it spit and sputtered and blew black smoke while increasing the throttle. We then stripped it of the deck and all related brackets/parts that were no longer needed. The clutch idler pulley was pretty much non existent, all that remained was the bearing from said pulley. We were able to get this belt to somehow work with this setup, and at very low speed, we were able to ride this thing around a bit before it threw the belt off. I purchased a new idler pulley, only to find out the drive belt that was on it was too short. So I’m holding off on buying another belt until we do a pulley swap (soon). Also added one new(er) rear tire. We also removed all safety switches and wired everything direct. As tempted as I am to make it a push start, I just can’t get rid of that “BEAST” key. I’ve had it for a week or so now, and didn’t plan on making a build thread for it. So pics of our work are sorta scarce. Here’s what we’ve got:   There she sits in the shop next to my LT2000 build. This thing looks pretty sharp. No major rust, most of the paint looks GREAT. Planning on repainting the whole thing (same color) eventually. It’s pretty nasty and we haven’t had a chance to pressure wash it yet due to the lack of a carb/air filter. As soon as they go on, it will get cleaned up.  Stock Carburetor came off for a 26mm Mikuni clone swap.

Last edited by WayneTrain2000 on April 20th 2020, 9:10 pm; edited 3 times in total | |

|

| |

WayneTrain2000

Member

Age : 22

Join date : 2019-11-16

Points : 1903

Posts : 80

Location : Augusta, GA

|  Subject: Re: “Beast” - Craftsman II Utility Build Subject: Re: “Beast” - Craftsman II Utility Build  December 15th 2019, 9:24 pm December 15th 2019, 9:24 pm | |

| The original carb was a one piece, so we couldn’t unbolt it and have a manifold to use with the new carb.  Intake manifold that was included with the new carb. The ends are turned the wrong way, therefore we can’t use it as is.  So in an attempt to make it work, I cut the ends off, mounted it up on the engine, and marked the way they need to be. Next week, I’m letting a friend attempt to TIG weld them on the right way. The piece could be destroyed, or it could work out. That being said, I’d like a plan B. If someone can link me to a (preferably cheap) intake manifold that will bolt right into this flathead, that would be greatly appreciated. That’s all I have for now, I will be documenting our modifications here as they happen. May take some more pics tomorrow. | |

|

| |

TheCollector

Member

2015 Build-Off Entrant

2015 Build-Off Entrant

2018 Build-Off Entrant

2018 Build-Off Entrant

2019 Build-Off Finalist

2019 Build-Off Finalist

Age : 38

Join date : 2015-04-22

Points : 3709

Posts : 194

Location : Bedias. Tx

| |

| |

CraftsmanQuad19

Veteran Member

2018 Build-Off Entrant

2018 Build-Off Entrant

2019 Build-Off Finalist

2019 Build-Off Finalist

Age : 24

Join date : 2016-04-12

Points : 5949

Posts : 2640

Location : Indiana

|  Subject: Re: “Beast” - Craftsman II Utility Build Subject: Re: “Beast” - Craftsman II Utility Build  December 15th 2019, 9:55 pm December 15th 2019, 9:55 pm | |

| You can also make an intake manifold out of conduit and large washers. Large washers being the flange and the conduit being the intake runner. Much easier material to work with | |

|

| |

WayneTrain2000

Member

Age : 22

Join date : 2019-11-16

Points : 1903

Posts : 80

Location : Augusta, GA

|  Subject: Re: “Beast” - Craftsman II Utility Build Subject: Re: “Beast” - Craftsman II Utility Build  December 15th 2019, 10:00 pm December 15th 2019, 10:00 pm | |

| If all else fails that’ll certainly be something to try. I still have a lot of 1” conduit from making an exhaust. Only thing is that stuff is really hard to weld without melting through. At least with a stick welder. I guess TIG is a different story, and that is an option. I have access to all processes one way or another. | |

|

| |

WayneTrain2000

Member

Age : 22

Join date : 2019-11-16

Points : 1903

Posts : 80

Location : Augusta, GA

|  Subject: Re: “Beast” - Craftsman II Utility Build Subject: Re: “Beast” - Craftsman II Utility Build  December 16th 2019, 5:02 pm December 16th 2019, 5:02 pm | |

| Had the manifold tack welded today and brought it home to test fit before welding 100%. Went down to TSC and got a 3” pulley for transaxle and 86” belt.  Manifold WORKS... but there is an issue. More info below.  The carb side flange was welded on crooked. This may have very well been my fault. I cut the tack welds and tried to make some better marks, hopefully we can get it lined up correctly tomorrow.  3” pulley on the transaxle. The 86” belt I purchased is too long, despite my calculation calling for ~85.5”. The rear clutch system on this thing seems like it’s going to be a pain. When the clutch is completely engaged, it pinches the belt between it and the shifter link. I didn’t take a pic of this unfortunately. I think I can resolve this with a shorter belt, I just don’t know how short. | |

|

| |

CraftsmanQuad19

Veteran Member

2018 Build-Off Entrant

2018 Build-Off Entrant

2019 Build-Off Finalist

2019 Build-Off Finalist

Age : 24

Join date : 2016-04-12

Points : 5949

Posts : 2640

Location : Indiana

| |

| |

Murraymountain

Veteran Member

2019 Build-Off Finalist

2019 Build-Off Finalist

2020 Build-Off Entrant

2020 Build-Off Entrant

2022 Build-Off Entrant

2022 Build-Off Entrant

Join date : 2019-02-04

Points : 4404

Posts : 2177

Location : North Carolina

|  Subject: Re: “Beast” - Craftsman II Utility Build Subject: Re: “Beast” - Craftsman II Utility Build  December 16th 2019, 6:16 pm December 16th 2019, 6:16 pm | |

| Eh, you might be able to get away with a 3". My brother runs a 3/4" on his and doesn't have any MAJOR issues.

Not trying to be the negative one here, BUT, that tranny would be a Peerless 930. My brother just blew one up with a 4" on it. You can run it, but I wouldn't. I'd run an MST. I have a Murray that's in the process of getting an MST swap. They're just simply better. Now a peerless 920 could be a whole different story. I've never tried one, but they look WAY beefier than a 930. | |

|

| |

WayneTrain2000

Member

Age : 22

Join date : 2019-11-16

Points : 1903

Posts : 80

Location : Augusta, GA

|  Subject: Re: “Beast” - Craftsman II Utility Build Subject: Re: “Beast” - Craftsman II Utility Build  December 16th 2019, 6:22 pm December 16th 2019, 6:22 pm | |

| What size pulley do y’all suggest I move up to? I really don’t know a sure fire way to swap the front pulley without messing up and having to buy more stuff... I’m completely open to running a larger rear pulley. It would probably help clutch issues I’m running into. I went and swapped for an 80” belt and it’s too short... guess I’m making the haul back to TSC tomorrow.

As for the rear end, I haven’t even thought about looking into which model it was. I don’t have any other rear ends and sure don’t have the cost of another one in the budget. So what do I need to do to play it safe? | |

|

| |

Rerun

Member

Join date : 2019-04-19

Points : 2104

Posts : 75

Location : Florida

|  Subject: Re: “Beast” - Craftsman II Utility Build Subject: Re: “Beast” - Craftsman II Utility Build  December 16th 2019, 7:39 pm December 16th 2019, 7:39 pm | |

| what size engine pulley you running? I wouldn't run a pulley smaller than 4" on the trans. Smaller pulleys will give you heat and slip issues. A 6/4 combo is a safe setup. | |

|

| |

WayneTrain2000

Member

Age : 22

Join date : 2019-11-16

Points : 1903

Posts : 80

Location : Augusta, GA

|  Subject: Re: “Beast” - Craftsman II Utility Build Subject: Re: “Beast” - Craftsman II Utility Build  December 16th 2019, 7:51 pm December 16th 2019, 7:51 pm | |

| Stock 3” on front and added a 3” on the rear today. Have not driven it because I’ve yet to find the correct belt. I went with the 3” simply because that’s what I’ve been running on the rear of my other tractor for several months without issue. How do I adapt a larger pulley to the engine shaft? | |

|

| |

Crazy_Carl

Veteran Member

2018 Build-Off Entrant

2018 Build-Off Entrant

2024 Build-Off Entrant

2024 Build-Off Entrant

Age : 35

Join date : 2017-10-30

Points : 5306

Posts : 2561

Location : Rochester, New York

|  Subject: Re: “Beast” - Craftsman II Utility Build Subject: Re: “Beast” - Craftsman II Utility Build  December 16th 2019, 8:25 pm December 16th 2019, 8:25 pm | |

| basically you'll need the correct hub that goes onto the crank, you'll have to weld a pulley to that. Do you already have a pulley? | |

|

| |

WayneTrain2000

Member

Age : 22

Join date : 2019-11-16

Points : 1903

Posts : 80

Location : Augusta, GA

|  Subject: Re: “Beast” - Craftsman II Utility Build Subject: Re: “Beast” - Craftsman II Utility Build  December 16th 2019, 10:22 pm December 16th 2019, 10:22 pm | |

| I don’t have any new pulleys, just the stock stacked pulley, which has a 6in on the bottom I believe? Is there a way to modify that one? Could you show me an example of the hub I’d need? | |

|

| |

CraftsmanQuad19

Veteran Member

2018 Build-Off Entrant

2018 Build-Off Entrant

2019 Build-Off Finalist

2019 Build-Off Finalist

Age : 24

Join date : 2016-04-12

Points : 5949

Posts : 2640

Location : Indiana

| |

| |

WayneTrain2000

Member

Age : 22

Join date : 2019-11-16

Points : 1903

Posts : 80

Location : Augusta, GA

| |

| |

CraftsmanQuad19

Veteran Member

2018 Build-Off Entrant

2018 Build-Off Entrant

2019 Build-Off Finalist

2019 Build-Off Finalist

Age : 24

Join date : 2016-04-12

Points : 5949

Posts : 2640

Location : Indiana

| |

| |

WayneTrain2000

Member

Age : 22

Join date : 2019-11-16

Points : 1903

Posts : 80

Location : Augusta, GA

|  Subject: Re: “Beast” - Craftsman II Utility Build Subject: Re: “Beast” - Craftsman II Utility Build  December 17th 2019, 9:26 am December 17th 2019, 9:26 am | |

| Oh, I see. I didn’t think those would work, because I don’t see a way of securing them to a shaft in a way that they won’t just fall off. Can I just buy a pulley with that hub already on it like the transaxle? How is that attached to the shaft? Just by set screws? | |

|

| |

redzz02

Site VIP

2014 Build-Off Entrant

2014 Build-Off Entrant

2016 Build-Off Top 3 Winner

2016 Build-Off Top 3 Winner

2021 Winner of Winners

2021 Winner of Winners

1st Place Build-Off 2015

1st Place Winner Build-Off 2015

1st Place Build-Off 2017

1st Place Build-Off Winner 2017

1st Place Build-Off 2018

1st Place Build-Off Winner 2018

Age : 29

Join date : 2010-05-12

Points : 6349

Posts : 899

Location : PA pittsburgh and pymatuning

|  Subject: Re: “Beast” - Craftsman II Utility Build Subject: Re: “Beast” - Craftsman II Utility Build  December 17th 2019, 9:55 am December 17th 2019, 9:55 am | |

| @WayneTrain2000 you weld the pulley to the hub, the hub has two set screws that if you loctite them before assembly I’ve rarely had one fall off, if you’re that worried about it set screw the pulley in place and the make a spacer out of 1 inch black plumbing pipe and use the factory crank bolt with a large washer, not only will you have set screws holding it in place, you will have the bolt to keep it from falling off, yes you can buy pulleys that are one piece with your desired bore size that also come with one or two set screws, stay away from cast aluminum pulleys | |

|

| |

WayneTrain2000

Member

Age : 22

Join date : 2019-11-16

Points : 1903

Posts : 80

Location : Augusta, GA

|  Subject: Re: “Beast” - Craftsman II Utility Build Subject: Re: “Beast” - Craftsman II Utility Build  December 17th 2019, 9:59 am December 17th 2019, 9:59 am | |

| Alright, guess I’ll give it a shot. I always buy the pre-made steel pulleys from TSC and never had a problem. I will probably keep my 3” since they took my receipt when I returned the belt... Maybe a 5” for the front? That would be equivalent to a 6/4.... | |

|

| |

redzz02

Site VIP

2014 Build-Off Entrant

2014 Build-Off Entrant

2016 Build-Off Top 3 Winner

2016 Build-Off Top 3 Winner

2021 Winner of Winners

2021 Winner of Winners

1st Place Build-Off 2015

1st Place Winner Build-Off 2015

1st Place Build-Off 2017

1st Place Build-Off Winner 2017

1st Place Build-Off 2018

1st Place Build-Off Winner 2018

Age : 29

Join date : 2010-05-12

Points : 6349

Posts : 899

Location : PA pittsburgh and pymatuning

|  Subject: Re: “Beast” - Craftsman II Utility Build Subject: Re: “Beast” - Craftsman II Utility Build  December 17th 2019, 10:03 am December 17th 2019, 10:03 am | |

| @WayneTrain2000 pre made steel pulleys will work just fine, a lot of people use the two part pulleys that you have to self weld because it’s a simple way to get a variety of sizes. There is nothing wrong with both styles | |

|

| |

WayneTrain2000

Member

Age : 22

Join date : 2019-11-16

Points : 1903

Posts : 80

Location : Augusta, GA

|  Subject: Re: “Beast” - Craftsman II Utility Build Subject: Re: “Beast” - Craftsman II Utility Build  December 17th 2019, 11:54 am December 17th 2019, 11:54 am | |

|  TIG welding currently in progress on the manifold. Going well for the most part, but there’s one part that he’s unable to weld. Not sure if this will cause a leak, or what I’ll need to do to seal it. Will update this afternoon. | |

|

| |

CraftsmanQuad19

Veteran Member

2018 Build-Off Entrant

2018 Build-Off Entrant

2019 Build-Off Finalist

2019 Build-Off Finalist

Age : 24

Join date : 2016-04-12

Points : 5949

Posts : 2640

Location : Indiana

| |

| |

Murraymountain

Veteran Member

2019 Build-Off Finalist

2019 Build-Off Finalist

2020 Build-Off Entrant

2020 Build-Off Entrant

2022 Build-Off Entrant

2022 Build-Off Entrant

Join date : 2019-02-04

Points : 4404

Posts : 2177

Location : North Carolina

|  Subject: Re: “Beast” - Craftsman II Utility Build Subject: Re: “Beast” - Craftsman II Utility Build  December 18th 2019, 10:23 am December 18th 2019, 10:23 am | |

| - WayneTrain2000 wrote:

As for the rear end, I haven’t even thought about looking into which model it was. I don’t have any other rear ends and sure don’t have the cost of another one in the budget. So what do I need to do to play it safe? Well, try not to do too many clutch dumps, don't run tires over 20" unless it's locked, and don't downshift hard (like from 6th to 2nd gear). That would be "playing it safe", but that doesn't guarantee anything. My brother blew the 930 up in 2nd gear with only one wheel turning... when he put his weight on that side it blew. So there's really no way to insure that it won't blow. I just like MSTs more than 930s, they're just stronger all the way around. If it ever does blow, look around at scrapyards for another tranny. You can get 'em dirt cheap over there. | |

|

| |

WayneTrain2000

Member

Age : 22

Join date : 2019-11-16

Points : 1903

Posts : 80

Location : Augusta, GA

|  Subject: Re: “Beast” - Craftsman II Utility Build Subject: Re: “Beast” - Craftsman II Utility Build  December 18th 2019, 10:28 am December 18th 2019, 10:28 am | |

| It has 18” tires now and I don’t plan to change them. I considered locking it but this seems to be a grease packed transaxle and I really don’t wanna get into it. I don’t really need to be locked for this build... I don’t really clutch dump or downshift often... so I guess it’s fine. Considering picking up a 5” pulley for front today if they have one, and actually measuring what length belt I need so I don’t have to screw around going back and forth to Tractor Supply. 86 was far too long, 80 was far too short, 83 almost made it over the rear pulley but would’ve been far too tight. So I’m guessing 84. But then I have to account for the 5” front... I don’t know, we’ll see. | |

|

| |

WayneTrain2000

Member

Age : 22

Join date : 2019-11-16

Points : 1903

Posts : 80

Location : Augusta, GA

|  Subject: Re: “Beast” - Craftsman II Utility Build Subject: Re: “Beast” - Craftsman II Utility Build  December 18th 2019, 10:36 am December 18th 2019, 10:36 am | |

| Alright, I’m just stumped at this point. I’ve tried just about every belt size from 80 to 87. I’ve been to tractor supply to exchange belts so many times they probably know me by my name. It’s either so tight that I can’t slip it over the pulley, or it’s so loose that the clutch comes back and completely collapses on the belt. I think at this point I’m gonna have to do away with this clutch system and build a new one in the middle/front of the tractor. If anyone could give me some really simple designs I’m ready to run with it. I’d like to keep materials that I have to buy at a minimum.  Swapped to a 4” pulley, hoping it would improve belt fitment.  Example of how the clutch pinches the belt between shifting link and belt keeper. I thought that if I got a short enough belt this wouldn’t happen, but a ‘short enough’ belt wouldn’t even go on the pulleys.

Last edited by WayneTrain2000 on December 18th 2019, 5:43 pm; edited 1 time in total | |

|

| |

Sponsored content

| |

| |

| | “Beast” - Craftsman II Utility Build |  |

|