| | Tracked craftsman |  |

|

+6frostypaws AllisKidD21 Lawren Wimberly MightyRaze prancstaman Camdg2010 10 posters |

|

| Author | Message |

|---|

prancstaman

Veteran Member

Join date : 2015-02-02

Posts : 1412

| |

| |

MightyRaze

Administrator

2017 Build-Off Finalist

2017 Build-Off Finalist

2018 Build-Off Top 3 Winner

2018 Build-Off Top 3 Winner

2019 Build-Off Top 3 Winner

2019 Build-Off Top 3 Winner

2021 Winner of Winners

2021 Winner of Winners

1st Place Build-Off 2022

1st Place Build-Off Winner 2022

10,000 POSTS!

10,000 POSTS!

2024 Build-Off Entrant

2024 Build-Off Entrant

Age : 49

Join date : 2016-09-06

Points : 15055

Posts : 10634

Location : Oklahoma

| |

| |

mr.modified

Veteran Member

2015 Build-Off Top 3 Winner

2015 Build-Off Top 3 Winner

2016 Build-Off Top 3 Winner

2016 Build-Off Top 3 Winner

2018 Build-Off Finalist

2018 Build-Off Finalist

2022 Build-Off Entrant

2022 Build-Off Entrant

1st Place Build-Off 2014

1st Place Build-Off Winner 2014

2023 Build-Off Entrant

2023 Build-Off Entrant

Age : 34

Join date : 2013-11-02

Points : 6954

Posts : 2906

Location : New Jersey USA

|  Subject: Re: Tracked craftsman Subject: Re: Tracked craftsman  May 13th 2017, 6:00 pm May 13th 2017, 6:00 pm | |

| Nice. I thought of using scrub brakes for something like this too. I think it would work ok if you made it with enough leverage. | |

|

| |

MatthewD

Veteran Member

2015 Build-Off Entrant

2015 Build-Off Entrant

2016 Build-Off Entrant

2016 Build-Off Entrant

Age : 22

Join date : 2014-11-16

Points : 5544

Posts : 1993

Location : Northern Ireland

| |

| |

Camdg2010

Member

Join date : 2014-01-22

Points : 3859

Posts : 94

|  Subject: Re: Tracked craftsman Subject: Re: Tracked craftsman  May 15th 2017, 12:56 pm May 15th 2017, 12:56 pm | |

| yes its got a 22 hp briggs v-twin, and zero turn wheel motors. cant wait to test drive this thing! may try to figure out the levers and linkages today if i dont have many tow calls

| |

|

| |

Camdg2010

Member

Join date : 2014-01-22

Points : 3859

Posts : 94

|  Subject: Re: Tracked craftsman Subject: Re: Tracked craftsman  May 15th 2017, 8:47 pm May 15th 2017, 8:47 pm | |

| well good news! it runs and drives. the bad news is, i didnt think it through when i swapped the wheel motors around, i figured if you push the control on the side of each wheel motor forward it would go forward... not the case, i had to run out to the scrap pile and sit on the old seat and look at it again, it pulls the coltrol backwards when you push the levers forward and vise versa... i have it so you push the levers forwards it pushes the control forward.. and to my suprize... it took off backwards! lol not what i was expecting.. its and easy fix and this fix will allow me to use my stock running boards for your feet where as the way i have it now the linkages from each lever to each control is in the way. i need the control to be pulled backwards ans i push the levers forwards.. or cut new slots in the frame and turn the wheel motors around the stock direction but then forward would actually be reverse. and my last project with one of these ended up going faster in "reverse (actually forwards for the zero turn) and slower forwards (reverse for the zero turn). i still dont have the tracks complete and another thing that im kind of irritated with is they didnt thread the exhaust port on the vtwin.. my opposed twin is threaded.. i wanted to put short stacks with one of those tractor supply lawn mower mufflers and a clap cap on each side... dont look likt thats going to happen unless i find a way to make new exhause tubing and flanges... more to come! | |

|

| |

Camdg2010

Member

Join date : 2014-01-22

Points : 3859

Posts : 94

| |

| |

TheBeal

Veteran Member

Age : 29

Join date : 2013-06-06

Points : 5504

Posts : 1398

Location : Central PA

| |

| |

MightyRaze

Administrator

2017 Build-Off Finalist

2017 Build-Off Finalist

2018 Build-Off Top 3 Winner

2018 Build-Off Top 3 Winner

2019 Build-Off Top 3 Winner

2019 Build-Off Top 3 Winner

2021 Winner of Winners

2021 Winner of Winners

1st Place Build-Off 2022

1st Place Build-Off Winner 2022

10,000 POSTS!

10,000 POSTS!

2024 Build-Off Entrant

2024 Build-Off Entrant

Age : 49

Join date : 2016-09-06

Points : 15055

Posts : 10634

Location : Oklahoma

|  Subject: Re: Tracked craftsman Subject: Re: Tracked craftsman  August 10th 2017, 12:47 am August 10th 2017, 12:47 am | |

| I almost forgot about this build! That thing is looking good! | |

|

| |

Camdg2010

Member

Join date : 2014-01-22

Points : 3859

Posts : 94

|  Subject: Re: Tracked craftsman Subject: Re: Tracked craftsman  August 13th 2017, 4:49 pm August 13th 2017, 4:49 pm | |

| ok guys, im having a little bit of track slip, i dont have any built in way to tighten the tracks, can what do you guys think i should do for tightening the tracks? and also, the tracks keep getting thrown when i make a 360 turn on it because there is nothing on the tracks to keep them from slipping off, so my idea is to get a 3rd set of drive cogs and put them at the front of the idler wheel arms on both sides, i have them in the rear already to keep them straight but thats not enough, so i would have the ones that drive the tracks on the hubs, then ones below that inplace of the front idler wheels then one on both sides in the rear making a total of 3 cogs on both sides... i think that would work... any thoughts? i tried a swing arm setup but that didnt work well... but i may be able to cut the idler wheel arms in the rear before the rear cogs and put in a piece of square tube inside the arms that slide and mount the rear cogs to it like it is now but have a grade 8 bolt to tighten the tracks... any ideas? | |

|

| |

Camdg2010

Member

Join date : 2014-01-22

Points : 3859

Posts : 94

|  Subject: Re: Tracked craftsman Subject: Re: Tracked craftsman  October 8th 2017, 5:08 pm October 8th 2017, 5:08 pm | |

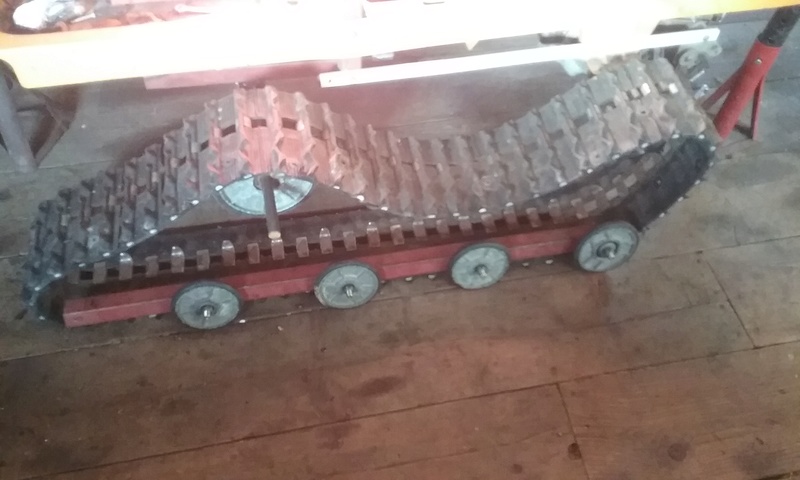

|  lil yard work. yes it actually pulled the stumps out. took a lil bit but it did it. now on to the nest beacuse this keeps throwing tracks. i need my fabricator friend to rebuild my undercarriage that the tracks run on | |

|

| |

Camdg2010

Member

Join date : 2014-01-22

Points : 3859

Posts : 94

| |

| |

redzz02

Site VIP

2014 Build-Off Entrant

2014 Build-Off Entrant

2016 Build-Off Top 3 Winner

2016 Build-Off Top 3 Winner

2021 Winner of Winners

2021 Winner of Winners

1st Place Build-Off 2015

1st Place Winner Build-Off 2015

1st Place Build-Off 2017

1st Place Build-Off Winner 2017

1st Place Build-Off 2018

1st Place Build-Off Winner 2018

Age : 29

Join date : 2010-05-12

Points : 6167

Posts : 899

Location : PA pittsburgh and pymatuning

|  Subject: Re: Tracked craftsman Subject: Re: Tracked craftsman  October 8th 2017, 7:33 pm October 8th 2017, 7:33 pm | |

| this is amazing! i love it! awesome work would love to see a video of it in action | |

|

| |

MightyRaze

Administrator

2017 Build-Off Finalist

2017 Build-Off Finalist

2018 Build-Off Top 3 Winner

2018 Build-Off Top 3 Winner

2019 Build-Off Top 3 Winner

2019 Build-Off Top 3 Winner

2021 Winner of Winners

2021 Winner of Winners

1st Place Build-Off 2022

1st Place Build-Off Winner 2022

10,000 POSTS!

10,000 POSTS!

2024 Build-Off Entrant

2024 Build-Off Entrant

Age : 49

Join date : 2016-09-06

Points : 15055

Posts : 10634

Location : Oklahoma

|  Subject: Re: Tracked craftsman Subject: Re: Tracked craftsman  October 8th 2017, 8:24 pm October 8th 2017, 8:24 pm | |

| - redzz02 wrote:

- would love to see a video of it in action

I agree, that would be sweet to see in a video! Thing looks even better and cooler now that it is out of the garage and doing work. Awesome Job! | |

|

| |

AllisKidD21

Moderator

2020 Build-Off Entrant

2020 Build-Off Entrant

1st Place Build-Off 2019

1st Place Build-Off Winner 2019

Age : 25

Join date : 2016-07-10

Points : 8378

Posts : 5190

Location : Ontario Canada

|  Subject: Re: Tracked craftsman Subject: Re: Tracked craftsman  October 8th 2017, 9:08 pm October 8th 2017, 9:08 pm | |

| That thing is sweet! Looks really cool and I bet it's pretty fun to drive.  "This'll either wake you up or put you to sleep forever!"- Red Green "Whatever you do you should do right, even if it's something wrong." - Hank Hill - MTD Off-Road Build

- Ford LT 110 Off-Road Build

- Craftsman GT 6000 Off-Road Build

- Sears LT11 Rat Rod Build *2019 Build-Off Winner!* Garden Tractor Collection: Allis B-110 x2, 710, 716, & 410 - Wheel Horse 655, 953 & 500 Special - Case 444 - Bolens Versamatic, G10 & 1668 Diesel Swapped - Cub 106, 124 & 1000/149 Frankentractor - Ford 120, LGT 125 & 145 - White 1650 Yard Boss - Moto Mower 710-100 | |

|

| |

Camdg2010

Member

Join date : 2014-01-22

Points : 3859

Posts : 94

|  Subject: Re: Tracked craftsman Subject: Re: Tracked craftsman  October 9th 2017, 8:59 pm October 9th 2017, 8:59 pm | |

| ok so im having some issues with this build. its wicked front heavy due to the motor being in the front, also i keep throwing tracks, i want to redo the setup, i want to make 2 big cogs for each side, one in front and one in back like a real dozer but i dont have any 3/4 steel plate or hard plastic, i want to make a prototype out of wood, im thinking 3/4 x 4 x8 foot sheet of white birch plywood to make the mock ups, if i cant afford or find anything, what do you guys think of using like maple or something, it needs to be strong, hard and not absorb water because after all its almost winter and that the reason i built this. what else could i use? i thought of car rims but as you can see i cut 1 track in half and used half for each side. i thought about like the diamiter of a bike rim but weld bolts on the rim to act as teeth but no way to drive it from wheel motors. i want to mention im thinking about making like 16-20 inch gears or cogs.. like the pic i included but not as big of a gap between them. any thoughts would help.  | |

|

| |

frostypaws

Member

2014 Build-Off Entrant

2014 Build-Off Entrant

Age : 29

Join date : 2012-07-01

Points : 4480

Posts : 131

Location : iowaaaa

|  Subject: Re: Tracked craftsman Subject: Re: Tracked craftsman  October 10th 2017, 7:54 pm October 10th 2017, 7:54 pm | |

| This might sound too caveman... but could you bolt up some pressure treated 2x6s near the bottom inside and outside track to take the lateral forces? If you want to get fancy, you could even put rollers to prevent wear from rubbing. One downside is it will trap material like snow and mud. Crude sketch below:  | |

|

| |

prancstaman

Veteran Member

Join date : 2015-02-02

Points : 4887

Posts : 1412

Location : Cleveland,Ohio

|  Subject: Re: Tracked craftsman Subject: Re: Tracked craftsman  October 10th 2017, 8:47 pm October 10th 2017, 8:47 pm | |

| Lookin good!!! A video would be good, but closeup pics of the track and ground wheels would help. I'm assuming to turn, you have to put one track in reverse to pivot because of no brakes. With you having the drive sprocket up front and high with the slanted down part and then to the ground wheels. Where the ground wheels start is probably where the track starts to come off since this spot has the most pressure on the tracks. Also looks to be single wheel ground wheels in a line, and lined up on the sprocket holes in the track. Looks like the tracks stay on pretty straight with little to no leaning to one side too.

The 2 big sprockets like in the dozer should do it on keeping the tracks on while turning, but that's a lot of redoing. I have an idea. You can bolt a C-channel on the opposite side of the ground wheels with the opening down. Fish mouth the ends so guides will channel into it to then straighten out while going through. Then you can use bolts as guides. Probably get away with between every other lug for a bolt, but if you got the money put a bolt between every lug , say a 3/8 size bolt and 1 1/2 inch long with washers on both sides so it don't pull through. The C-channel that is used for hanging electrical conduit would be prefect.

To help with the turning. You have 4 ground wheels in a line. Replace the 2 front ground wheels with wheels 1 inch bigger. This will help tighten up the tracks and focus the ground pressure on the 2 front ground wheels. So when you turn, the 2 rear ground wheels will swing instead of skidding across the ground. This will also help with not throwing a track while turning. The 2 front ground wheels should also be able to handle double the weight also since these 2 wheels are only on the ground while on hard surfaces. Now when on soft surfaces, the transition point from the 2 front wheels to the 2 back wheels will sink in soft surfaces for added weight distribution and traction.

The edges of the tracks, you can bevel them so when you turn, the edges will slide over the ground. If the edges are straight up and down, when you turn they will be plowing through the ground. The little thing help a lot here.

Hope it steers you in the right direction. | |

|

| |

Sponsored content

| |

| |

| | Tracked craftsman |  |

|