| | Craftsman Lt2000 Project |  |

|

+20Ariens YT11 jamcco ZSmachines mr.modified 98Murray Jerbear0612 Ozzy's Creations 1997 Murray CornShuck4CE countryboy12894 craftsmancole Angchor tanis Creepycrawler TheRainbowBoxer camomanusa LAWN MOWER MUDDER redlinemotorsportts richie thomas willis923 24 posters |

|

| Author | Message |

|---|

Creepycrawler

Established Member

2024 Build-Off Entrant

2024 Build-Off Entrant

Join date : 2013-07-02

Posts : 731

|  Subject: Re: Craftsman Lt2000 Project Subject: Re: Craftsman Lt2000 Project  April 25th 2014, 4:45 pm April 25th 2014, 4:45 pm | |

| Cool man, I like the 4 link. like others have said very clean. I would highly recommend doing a "doc locker" by far the best "locker" setup Ive seen. that fozzy locker is a time bomb. | |

|

| |

craftsmancole

Established Member

2015 Build-Off Entrant

2015 Build-Off Entrant

Age : 25

Join date : 2013-04-05

Points : 4845

Posts : 661

Location : New Smyrna Beach,Fl

|  Subject: Re: Craftsman Lt2000 Project Subject: Re: Craftsman Lt2000 Project  April 25th 2014, 5:51 pm April 25th 2014, 5:51 pm | |

| - jamcco wrote:

- oh i ended up going with the fozzy locker. i figured the mst 206 could take it i went for a quick drive with the 4 link and i need to do some adjustments but other than that it drives way smoother

Alright, I think a 206 can take it too, I forget if mst's have them stock but if not next you pull it apart I would replace the axle bushings with bearings. | |

|

| |

jamcco

Member

Age : 25

Join date : 2014-01-04

Points : 4099

Posts : 226

Location : New Hampshire

|  Subject: Re: Craftsman Lt2000 Project Subject: Re: Craftsman Lt2000 Project  April 25th 2014, 8:11 pm April 25th 2014, 8:11 pm | |

| - countryboy12894 wrote:

- Sweet build! liking the way its going so far!

thanks its got alot of flaws so far that still need to be worked out - I would highly recommend doing a "doc locker" by far the best "locker" setup Ive seen. that fozzy locker is a time bomb. wrote:

the doc locker would be neat, ive heard mixed reviews on the fozzy as well. some say it works some say it doesnt. i honestly haven't locked a transaxle before and i gambled with the fozzy. like i said before i hope what you say doesnt happen but if it does im sure i'll hear it from yah lol - Alright, I think a 206 can take it too, I forget if mst's have them stock but if not next you pull it apart I would replace the axle bushings with bearings. wrote:

yah that would be a great idea. that would probably make things last a little bit longer. | |

|

| |

jamcco

Member

Age : 25

Join date : 2014-01-04

Points : 4099

Posts : 226

Location : New Hampshire

|  Subject: Re: Craftsman Lt2000 Project Subject: Re: Craftsman Lt2000 Project  April 26th 2014, 10:39 pm April 26th 2014, 10:39 pm | |

| i redid my exhaust and i welded it up better than i did the first time around. i actually made it quieter which is the opposite of what i was trying to do. i think that ill add a echo chamber or something after my atv muffler. sort of like a fart can | |

|

| |

Ariens YT11

Established Member

2014 Build-Off Entrant

2014 Build-Off Entrant

2015 Build-Off Entrant

2015 Build-Off Entrant

Age : 27

Join date : 2012-10-31

Points : 5047

Posts : 745

Location : The Wyo-Braska Panhandle

|  Subject: Re: Craftsman Lt2000 Project Subject: Re: Craftsman Lt2000 Project  April 28th 2014, 7:58 pm April 28th 2014, 7:58 pm | |

| can you get some more pics of your setup? I'm trying to get an idea on how to set mine up? | |

|

| |

jamcco

Member

Age : 25

Join date : 2014-01-04

Points : 4099

Posts : 226

Location : New Hampshire

|  Subject: Re: Craftsman Lt2000 Project Subject: Re: Craftsman Lt2000 Project  April 28th 2014, 8:41 pm April 28th 2014, 8:41 pm | |

| no problem i'll try to get some tommorow. anything in particular that you would like to see? | |

|

| |

CornShuck4CE

Member

Age : 35

Join date : 2014-04-07

Points : 4119

Posts : 337

Location : Woodville Al

|  Subject: Re: Craftsman Lt2000 Project Subject: Re: Craftsman Lt2000 Project  April 28th 2014, 8:47 pm April 28th 2014, 8:47 pm | |

| Well then a friend rivelry. Hmmmm i can see this getting carried away. Haha. Cant wait to see both your rigs rippin it up. Cant wait to start the rear but i usualy dont start projects till i have the stuff finish it. | |

|

| |

Ariens YT11

Established Member

2014 Build-Off Entrant

2014 Build-Off Entrant

2015 Build-Off Entrant

2015 Build-Off Entrant

Age : 27

Join date : 2012-10-31

Points : 5047

Posts : 745

Location : The Wyo-Braska Panhandle

|  Subject: Re: Craftsman Lt2000 Project Subject: Re: Craftsman Lt2000 Project  April 28th 2014, 8:48 pm April 28th 2014, 8:48 pm | |

| pretty much where you mounted to to the frame and the axle. only diff with my AYP chassis is that I have the cast axle. | |

|

| |

Ariens YT11

Established Member

2014 Build-Off Entrant

2014 Build-Off Entrant

2015 Build-Off Entrant

2015 Build-Off Entrant

Age : 27

Join date : 2012-10-31

Points : 5047

Posts : 745

Location : The Wyo-Braska Panhandle

|  Subject: Re: Craftsman Lt2000 Project Subject: Re: Craftsman Lt2000 Project  April 28th 2014, 8:50 pm April 28th 2014, 8:50 pm | |

| - CornShuck4CE wrote:

- Well then a friend rivelry. Hmmmm i can see this getting carried away. Haha. Cant wait to see both your rigs rippin it up. Cant wait to start the rear but i usualy dont start projects till i have the stuff finish it.

I more so need it on the front since I do alot at 20MPH on dirt roads. they get rough and sometimes with 5psi in the front tires the bumps still hurt. | |

|

| |

CornShuck4CE

Member

Age : 35

Join date : 2014-04-07

Points : 4119

Posts : 337

Location : Woodville Al

|  Subject: Re: Craftsman Lt2000 Project Subject: Re: Craftsman Lt2000 Project  April 28th 2014, 8:59 pm April 28th 2014, 8:59 pm | |

| My mower runs 30mph and it does so good with this setup and steering im thinking of bumpin it up some more. | |

|

| |

jamcco

Member

Age : 25

Join date : 2014-01-04

Points : 4099

Posts : 226

Location : New Hampshire

|  Subject: Re: Craftsman Lt2000 Project Subject: Re: Craftsman Lt2000 Project  April 28th 2014, 9:02 pm April 28th 2014, 9:02 pm | |

| cornshuck: pssh ive got this rivalary under control....sorta

ariens: i have some changes to make to my design but it will probably give you the tips you need as she sits....also i had a cast iron axle but i was able to swap out a stamped steel one that i had on my "parts" tractor. this set up would help alot with that dirt road of yours....it helps absorbs the bumps way better, also makes cornering less of a mess. | |

|

| |

CornShuck4CE

Member

Age : 35

Join date : 2014-04-07

Points : 4119

Posts : 337

Location : Woodville Al

|  Subject: Re: Craftsman Lt2000 Project Subject: Re: Craftsman Lt2000 Project  April 28th 2014, 9:27 pm April 28th 2014, 9:27 pm | |

| Smart to mock it up with stamped axel. I had a couple murray axels layen around just in case i didnt like something i did. | |

|

| |

Ariens YT11

Established Member

2014 Build-Off Entrant

2014 Build-Off Entrant

2015 Build-Off Entrant

2015 Build-Off Entrant

Age : 27

Join date : 2012-10-31

Points : 5047

Posts : 745

Location : The Wyo-Braska Panhandle

|  Subject: Re: Craftsman Lt2000 Project Subject: Re: Craftsman Lt2000 Project  April 28th 2014, 9:42 pm April 28th 2014, 9:42 pm | |

| that is the lugury I don't got with the spare axles, and depening on how well this goes on my romper I'll do it to my racer I'm gonna do. | |

|

| |

jamcco

Member

Age : 25

Join date : 2014-01-04

Points : 4099

Posts : 226

Location : New Hampshire

|  Subject: Re: Craftsman Lt2000 Project Subject: Re: Craftsman Lt2000 Project  April 28th 2014, 9:43 pm April 28th 2014, 9:43 pm | |

| i have 1 spare set of everything due to that parts mower and i bet you might be able to get something to work with a cast iron front axle

| |

|

| |

Ariens YT11

Established Member

2014 Build-Off Entrant

2014 Build-Off Entrant

2015 Build-Off Entrant

2015 Build-Off Entrant

Age : 27

Join date : 2012-10-31

Points : 5047

Posts : 745

Location : The Wyo-Braska Panhandle

| |

| |

jamcco

Member

Age : 25

Join date : 2014-01-04

Points : 4099

Posts : 226

Location : New Hampshire

|  Subject: Re: Craftsman Lt2000 Project Subject: Re: Craftsman Lt2000 Project  April 29th 2014, 4:31 pm April 29th 2014, 4:31 pm | |

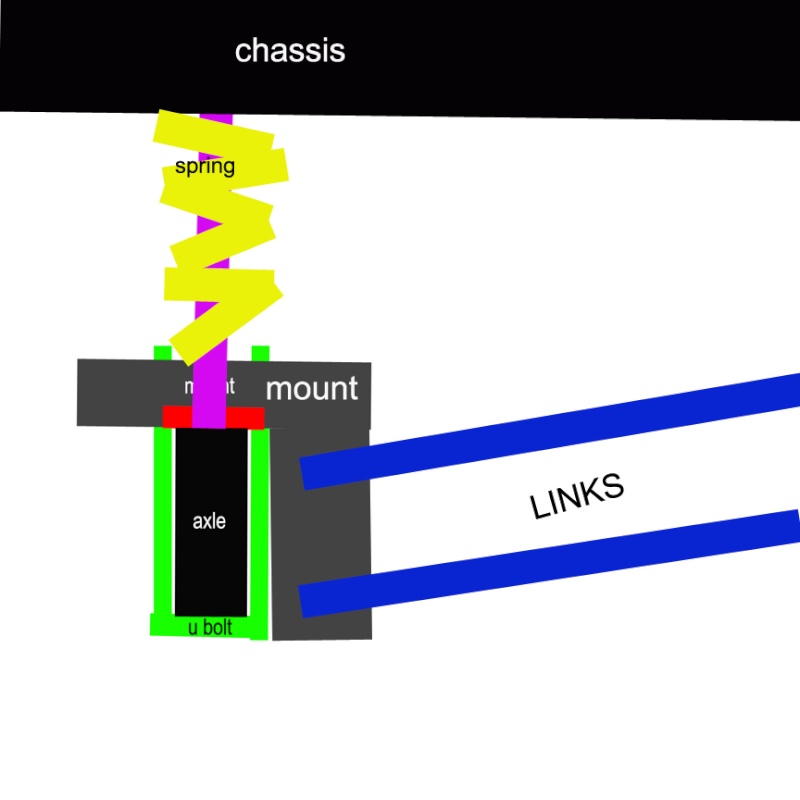

| ok ariens, heres some quick pictures of my set up  this is the brackets on the axle....all i did was take some angle iron from a shelving unit and cut it to length  this is the shock tower, some bed frame acts as the uprights and shock mount and the shelving acts as a support  my panhard bar is one of the deck height linkages that i straightened out and welded a bolt onto. one end goes into a mount i made and the bolt goes right through the axle  this is the mount where the panhard pins into  i then mounted the other half of the 4 links directly to the frame. i am doing some frame reinforcements soon i also bolted the shocks to the axle this setup works, but is going to get alot more work to make it more reliable i think that if you made your coil and 4 link mounts as one whole unit, you could then simply be able to U bolt the mounts to the axle....i say this because i have never welded cast iron before and ive heard that it isnt the easiest to weld | |

|

| |

Ariens YT11

Established Member

2014 Build-Off Entrant

2014 Build-Off Entrant

2015 Build-Off Entrant

2015 Build-Off Entrant

Age : 27

Join date : 2012-10-31

Points : 5047

Posts : 745

Location : The Wyo-Braska Panhandle

| |

| |

jamcco

Member

Age : 25

Join date : 2014-01-04

Points : 4099

Posts : 226

Location : New Hampshire

| |

| |

Ariens YT11

Established Member

2014 Build-Off Entrant

2014 Build-Off Entrant

2015 Build-Off Entrant

2015 Build-Off Entrant

Age : 27

Join date : 2012-10-31

Points : 5047

Posts : 745

Location : The Wyo-Braska Panhandle

|  Subject: Re: Craftsman Lt2000 Project Subject: Re: Craftsman Lt2000 Project  April 29th 2014, 9:39 pm April 29th 2014, 9:39 pm | |

| I am too, I just need to get stuff readygonna start getting the 2"x2" angle iron ready and cut tomarrow.

then I'm gonna start getting my stray seat springs and other stiff springs ready since I have no coil-over springs.

I might be getting car hood shocks for the shocks themselves later.

| |

|

| |

jamcco

Member

Age : 25

Join date : 2014-01-04

Points : 4099

Posts : 226

Location : New Hampshire

| |

| |

Ariens YT11

Established Member

2014 Build-Off Entrant

2014 Build-Off Entrant

2015 Build-Off Entrant

2015 Build-Off Entrant

Age : 27

Join date : 2012-10-31

Points : 5047

Posts : 745

Location : The Wyo-Braska Panhandle

|  Subject: Re: Craftsman Lt2000 Project Subject: Re: Craftsman Lt2000 Project  April 29th 2014, 10:05 pm April 29th 2014, 10:05 pm | |

| Well I'll be making it so I can put real springs on it eventually but not till I get more cash, allready spent close to a hinderd bucks on a phone and plan. because I got in trouble for not telling my mom I was gonna stay after school to work on a Math test. | |

|

| |

jamcco

Member

Age : 25

Join date : 2014-01-04

Points : 4099

Posts : 226

Location : New Hampshire

|  Subject: Re: Craftsman Lt2000 Project Subject: Re: Craftsman Lt2000 Project  April 29th 2014, 10:15 pm April 29th 2014, 10:15 pm | |

| money sucks  its always getting in the way of projects. the seat springs should work, set them up like coils you could possibly make this with seat springs  | |

|

| |

Ariens YT11

Established Member

2014 Build-Off Entrant

2014 Build-Off Entrant

2015 Build-Off Entrant

2015 Build-Off Entrant

Age : 27

Join date : 2012-10-31

Points : 5047

Posts : 745

Location : The Wyo-Braska Panhandle

|  Subject: Re: Craftsman Lt2000 Project Subject: Re: Craftsman Lt2000 Project  May 3rd 2014, 9:26 pm May 3rd 2014, 9:26 pm | |

| That is basicly what I'm doing. I need to lookinto how to hook them up more now that I have the spots ready for my stuff.

| |

|

| |

CornShuck4CE

Member

Age : 35

Join date : 2014-04-07

Points : 4119

Posts : 337

Location : Woodville Al

|  Subject: Re: Craftsman Lt2000 Project Subject: Re: Craftsman Lt2000 Project  May 3rd 2014, 10:19 pm May 3rd 2014, 10:19 pm | |

| Dont know about yal but im about 170 pounds and i just about bottom my springs out. If you added the weight of the rear of the mower they might stay bottomed out. You need stronger springs. Especially when hitting rough terrain. | |

|

| |

jamcco

Member

Age : 25

Join date : 2014-01-04

Points : 4099

Posts : 226

Location : New Hampshire

|  Subject: Re: Craftsman Lt2000 Project Subject: Re: Craftsman Lt2000 Project  May 3rd 2014, 10:40 pm May 3rd 2014, 10:40 pm | |

| to accomadate the cast iron axle......once again i have no idea how it welds. but this is a quick sketch i made that would allow you to bolt your axle to the system......i dont know if this sketch makes sense to anyone else and if i made a mistake anywhere just point it out, like i said its just an idea this could also be a guide to make a complete bolt together suspension  and yah i was just thinking that myself if you dont have mini quad shocks you might want to possibly invest in it or if you want to do a springed suspension you might want to find some heavier springs.... | |

|

| |

Ariens YT11

Established Member

2014 Build-Off Entrant

2014 Build-Off Entrant

2015 Build-Off Entrant

2015 Build-Off Entrant

Age : 27

Join date : 2012-10-31

Points : 5047

Posts : 745

Location : The Wyo-Braska Panhandle

|  Subject: Re: Craftsman Lt2000 Project Subject: Re: Craftsman Lt2000 Project  May 3rd 2014, 11:20 pm May 3rd 2014, 11:20 pm | |

| Ok I got today some 2x2 angle iron cut and "Bolted" to the axle, I used a #5 carrage bolt to mount to the axle since there is a hole in the axle for eye bolts or something to mount to the front end for the pivot??? I think that will work fine till I can get enough steel for a homemade front axle. and on the springs, I got two diff, sizes and stiffness springs, I was thinking I coulld double them up. I will have more info on this tomarrow as I am gonna be updating my project anyways. | |

|

| |

Sponsored content

| |

| |

| | Craftsman Lt2000 Project |  |

|