| | Simplicity Broadmoor R/S Project |  |

|

+17Hillbilly Offroading redzz02 muddstir redlinemotorsportts prancstaman mrshaft696 MightyRaze JohnLidell diddie TheBeal mowerjunkie03 RichieRichOverdrive Mister_Studabaker Creepycrawler AllisKidD21 CraftsmanQuad19 mr.modified 21 posters |

|

| Author | Message |

|---|

mr.modified

Veteran Member

2015 Build-Off Top 3 Winner

2015 Build-Off Top 3 Winner

2016 Build-Off Top 3 Winner

2016 Build-Off Top 3 Winner

2018 Build-Off Finalist

2018 Build-Off Finalist

2022 Build-Off Entrant

2022 Build-Off Entrant

1st Place Build-Off 2014

1st Place Build-Off Winner 2014

2023 Build-Off Entrant

2023 Build-Off Entrant

Join date : 2013-11-02

Posts : 2907

|  Subject: Re: Simplicity Broadmoor R/S Project Subject: Re: Simplicity Broadmoor R/S Project  February 7th 2020, 5:07 pm February 7th 2020, 5:07 pm | |

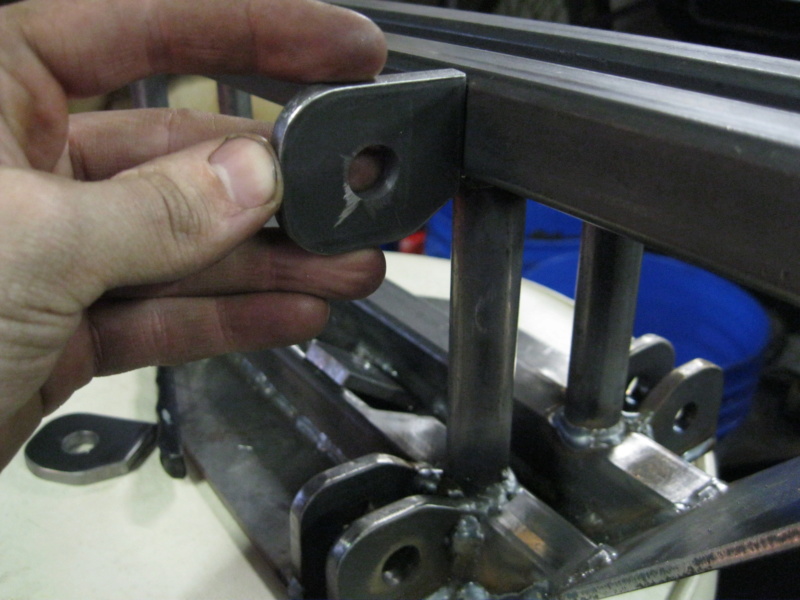

| The suspension bracket making process at Simplicity's racing division... As usual when making a super high tech part, we start with a cardboard template (Labeled as such to prevent accidental disposal) I center punch the hole with the template also while keeping the important flat surfaces that will touch the frame flush with the template.  I drill the hole before making any cuts. That makes it much easier to work with in the drill press. Or to clamp it in a vice for a hand drill. Then make the cuts with a sawzall. On the tabs for the lower suspension, I only rounded one of the outter edges because the bottom butted up against the skid plate. The top ones will stick out in mid air, so both edges get rounded off.  I finish rounding the edges with a normal bench grinder and wire wheel. The most important thing is that the holes are all as close as possible, but the edges seem to come out pretty close as long as I'm careful to always mark and cut about the same way.  Once welded to the frame, I can correct any slight hole alignment issues by running a drill bit through it to ream them out a little. There are of course eight bottom tabs for both lower control arms and eight upper tabs for the upper control arms. Plus there will need to be eight tabs to mount both front shocks (two tabs for top and bottom each) And then later on, mounting tabs for the rear shocks....For now I'll try not to think about how many more I have to cut out.  | |

|

| |

Creepycrawler

Established Member

2024 Build-Off Entrant

2024 Build-Off Entrant

Age : 37

Join date : 2013-07-02

Points : 4992

Posts : 731

Location : Logan Ohio

| |

| |

Doug

Site Owner

2014 Build-Off Entrant

2014 Build-Off Entrant

2017 Build-Off Entrant

2017 Build-Off Entrant

Age : 29

Join date : 2012-12-24

Points : 7752

Posts : 3044

Location : Lebanon County, PA

| |

| |

mr.modified

Veteran Member

2015 Build-Off Top 3 Winner

2015 Build-Off Top 3 Winner

2016 Build-Off Top 3 Winner

2016 Build-Off Top 3 Winner

2018 Build-Off Finalist

2018 Build-Off Finalist

2022 Build-Off Entrant

2022 Build-Off Entrant

1st Place Build-Off 2014

1st Place Build-Off Winner 2014

2023 Build-Off Entrant

2023 Build-Off Entrant

Age : 34

Join date : 2013-11-02

Points : 7137

Posts : 2907

Location : New Jersey USA

| |

| |

mr.modified

Veteran Member

2015 Build-Off Top 3 Winner

2015 Build-Off Top 3 Winner

2016 Build-Off Top 3 Winner

2016 Build-Off Top 3 Winner

2018 Build-Off Finalist

2018 Build-Off Finalist

2022 Build-Off Entrant

2022 Build-Off Entrant

1st Place Build-Off 2014

1st Place Build-Off Winner 2014

2023 Build-Off Entrant

2023 Build-Off Entrant

Age : 34

Join date : 2013-11-02

Points : 7137

Posts : 2907

Location : New Jersey USA

| |

| |

mr.modified

Veteran Member

2015 Build-Off Top 3 Winner

2015 Build-Off Top 3 Winner

2016 Build-Off Top 3 Winner

2016 Build-Off Top 3 Winner

2018 Build-Off Finalist

2018 Build-Off Finalist

2022 Build-Off Entrant

2022 Build-Off Entrant

1st Place Build-Off 2014

1st Place Build-Off Winner 2014

2023 Build-Off Entrant

2023 Build-Off Entrant

Age : 34

Join date : 2013-11-02

Points : 7137

Posts : 2907

Location : New Jersey USA

|  Subject: Re: Simplicity Broadmoor R/S Project Subject: Re: Simplicity Broadmoor R/S Project  February 13th 2020, 1:22 am February 13th 2020, 1:22 am | |

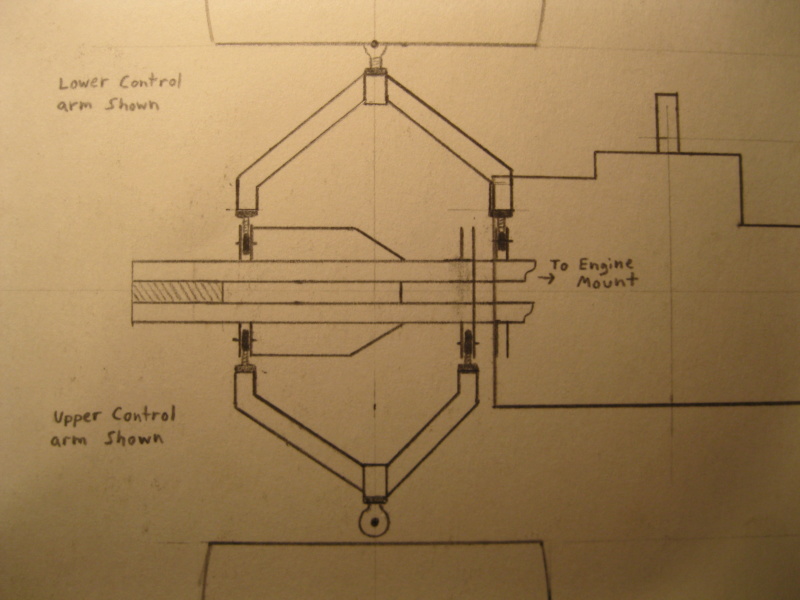

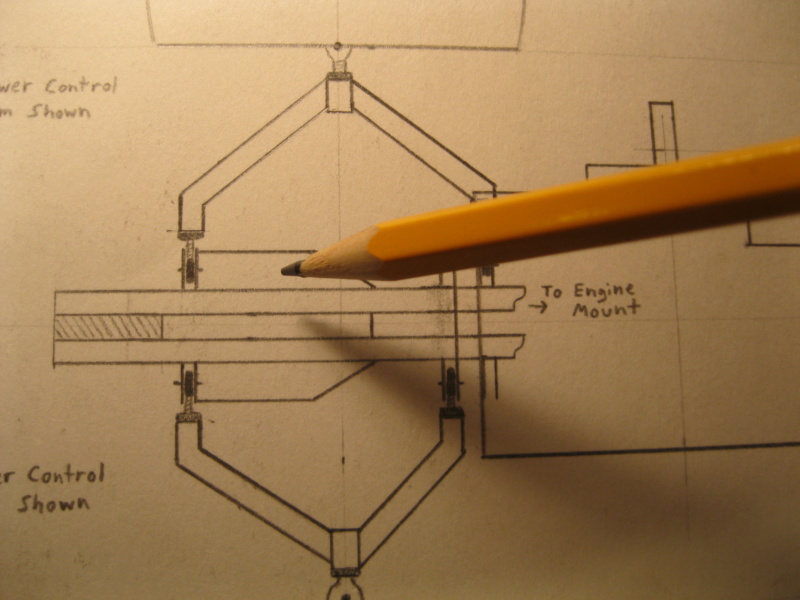

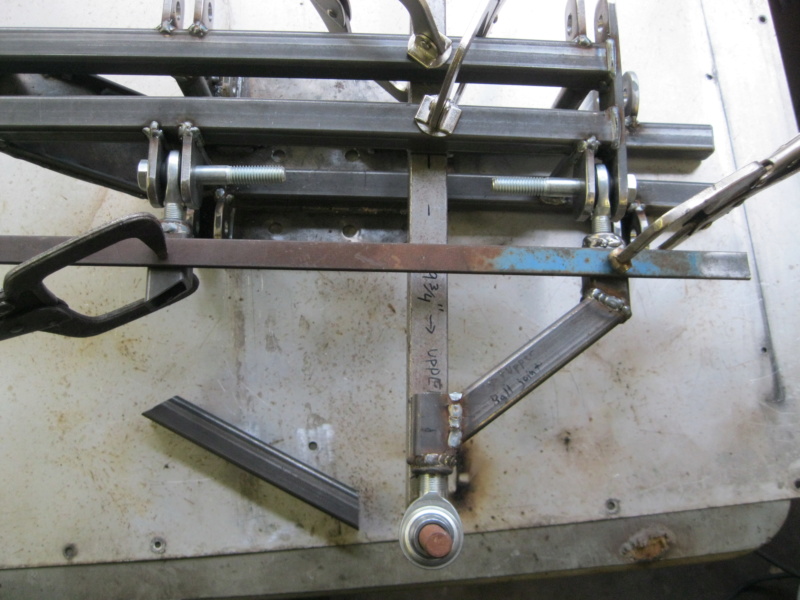

| With the front frame welded up, I decided to add it to the drawing and get an idea what the control arms will look like. Planning on the same 1" square tube I used for the frame. Since the upper and lower arms are slightly different, I showed the lower arm at the top and upper arm on the bottom (as indicated on the drawing). You might notice that the upper and lower arm attachment points at the wheel are slightly different. That's because the golf cart spindles are tipped at an angle (forget what it's called) Not really camber because the wheel is straight. Not exactly caster either, I'm sure there's a name for it. Anyway, point is, upper and lower attachment points at the wheel are about 1" difference. Lower point is about in line with the inside edge of the tire, with the upper attachment point about 1" towards the middle of the tractor.  The coil over shocks will be connected to the lower arm. The top of the coil overs will be connected to a bracket off the top of the frame. But I need to keep in mind that the steering shaft will have to come through where the pencil is in this pic. So the shocks can't be tipped too far in towards the center or the right one would foul the shaft. Once I make the arms I can figure out where the shocks need to be. Over all I think the front end will be pretty rugged. One point I'm worried about is if the lower heims will be strong enough. The entire weight of the machine will rest on the lower joints with the weak point being between where they thread into the lower arms and the joint itself. I hope they don't snap off. If it becomes a serious issue, I'm sure I could change the lower arms and make something else fit. At this point I don't really know any other easy way to do it while using the golf cart spindles. Not exactly sure if they are meant for that kind of wear either but we'll see.  | |

|

| |

CraftsmanQuad19

Veteran Member

2018 Build-Off Entrant

2018 Build-Off Entrant

2019 Build-Off Finalist

2019 Build-Off Finalist

Age : 24

Join date : 2016-04-12

Points : 5949

Posts : 2640

Location : Indiana

|  Subject: Re: Simplicity Broadmoor R/S Project Subject: Re: Simplicity Broadmoor R/S Project  February 13th 2020, 11:09 am February 13th 2020, 11:09 am | |

| The knuckles being tipped inwards like that are for your caster arc. I assume that’s what you’re talking about. Knuckle tilts in but the spindle sticks off of it parallel to the ground. That’s what’s considered a Short Long Arm (SLA for short) suspension setup where the upper control arm is shorter than the lower control arm. This is used in automotive applications that use an upper and lower control arm setup. When the suspension is compressed the top of the tire tilts in (negative camber I think) and can give you a little more stability.

Are you going to run a swaybar on this? Perhaps a quick disconnect bar so you can connect it real quick for high speed obstacle courses and disconnect it for maximum articulation for crawling. You could attach it to the upper control arm and mount it to the top of the chassis for easy access. Not sure if you’ve mentioned the idea before and I missed it | |

|

| |

mr.modified

Veteran Member

2015 Build-Off Top 3 Winner

2015 Build-Off Top 3 Winner

2016 Build-Off Top 3 Winner

2016 Build-Off Top 3 Winner

2018 Build-Off Finalist

2018 Build-Off Finalist

2022 Build-Off Entrant

2022 Build-Off Entrant

1st Place Build-Off 2014

1st Place Build-Off Winner 2014

2023 Build-Off Entrant

2023 Build-Off Entrant

Age : 34

Join date : 2013-11-02

Points : 7137

Posts : 2907

Location : New Jersey USA

|  Subject: Re: Simplicity Broadmoor R/S Project Subject: Re: Simplicity Broadmoor R/S Project  February 13th 2020, 9:48 pm February 13th 2020, 9:48 pm | |

| That's what I was talking about yeah. And have not thought much about using a sway bar. It would be an ok idea but I think I'll just leave it open to start with. Later on I could always add one in if the roll was too much. | |

|

| |

Creepycrawler

Established Member

2024 Build-Off Entrant

2024 Build-Off Entrant

Age : 37

Join date : 2013-07-02

Points : 4992

Posts : 731

Location : Logan Ohio

|  Subject: Re: Simplicity Broadmoor R/S Project Subject: Re: Simplicity Broadmoor R/S Project  February 14th 2020, 11:10 pm February 14th 2020, 11:10 pm | |

| I believe what your talking about is KPI or kingpin inclination angle. But I’ve been wrong before. Love the drawings by the way | |

|

| |

mr.modified

Veteran Member

2015 Build-Off Top 3 Winner

2015 Build-Off Top 3 Winner

2016 Build-Off Top 3 Winner

2016 Build-Off Top 3 Winner

2018 Build-Off Finalist

2018 Build-Off Finalist

2022 Build-Off Entrant

2022 Build-Off Entrant

1st Place Build-Off 2014

1st Place Build-Off Winner 2014

2023 Build-Off Entrant

2023 Build-Off Entrant

Age : 34

Join date : 2013-11-02

Points : 7137

Posts : 2907

Location : New Jersey USA

|  Subject: Re: Simplicity Broadmoor R/S Project Subject: Re: Simplicity Broadmoor R/S Project  February 15th 2020, 12:18 pm February 15th 2020, 12:18 pm | |

| I'll be the first to admit I have no idea what the technical term for it is. Looks to me like it would make the steering want to return to center more. I figured if it worked ok for the golf cart I'll keep it the same.

Thanks about the drawings, helps a little bit to see how things are gonna go without holding a bunch of stuff and measuring everything wrong. Plus it's always there to go back to.

I've been thinking over some various suspension options. I think I may get some bigger heims with 7/8 ID to fit over the sleeves for the lower ball joints. Looked at some pics online and there are other ways I could rig it up, but just using heims seems to be the easiest route without a lot of extra fabrication. Just worried about the front end being held up on a 1/2" rod. I'm thinking after a while it may fatigue and sheer off. | |

|

| |

Creepycrawler

Established Member

2024 Build-Off Entrant

2024 Build-Off Entrant

Age : 37

Join date : 2013-07-02

Points : 4992

Posts : 731

Location : Logan Ohio

| |

| |

mr.modified

Veteran Member

2015 Build-Off Top 3 Winner

2015 Build-Off Top 3 Winner

2016 Build-Off Top 3 Winner

2016 Build-Off Top 3 Winner

2018 Build-Off Finalist

2018 Build-Off Finalist

2022 Build-Off Entrant

2022 Build-Off Entrant

1st Place Build-Off 2014

1st Place Build-Off Winner 2014

2023 Build-Off Entrant

2023 Build-Off Entrant

Age : 34

Join date : 2013-11-02

Points : 7137

Posts : 2907

Location : New Jersey USA

|  Subject: Re: Simplicity Broadmoor R/S Project Subject: Re: Simplicity Broadmoor R/S Project  February 16th 2020, 11:12 pm February 16th 2020, 11:12 pm | |

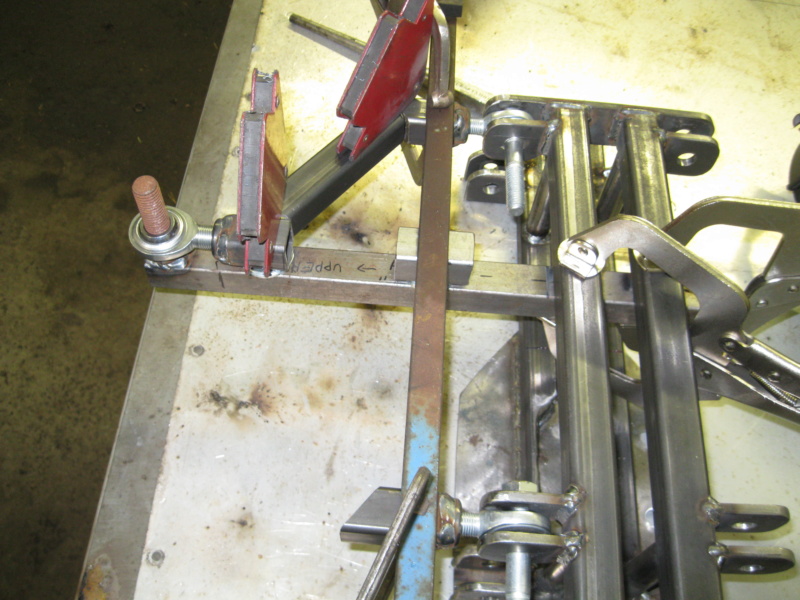

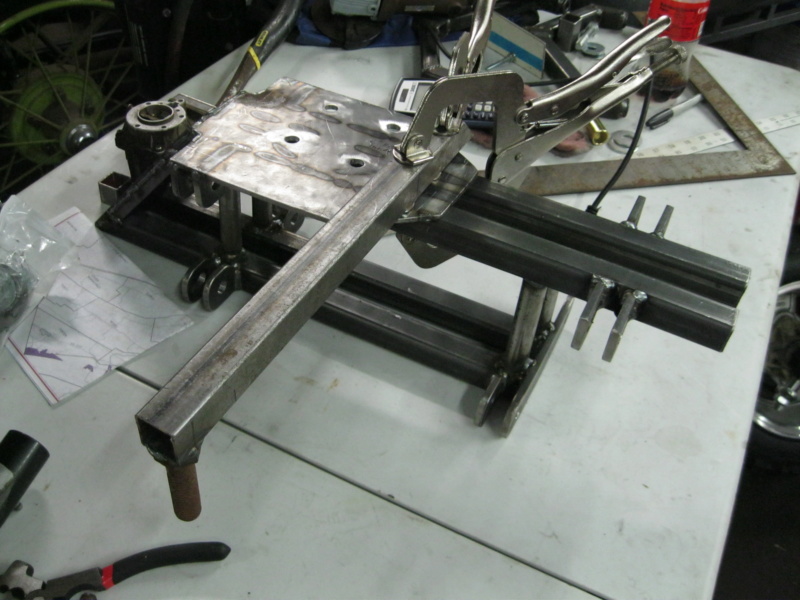

| Actually I made a mistake, the ball joint ends were 5/8 and the control arm pivot joints are half inch. But even so, I still wanted to go bigger. So I stopped at tractor supply today and got some SUPER RIDICULOUS OVERKILL 7/8" BORE HASPIN TOUGH joints. So there we go. Some weldable 7/8" joints that I'll weld into the lower arms. They're a little bit heavy but I don't think I'll have any issues with them breaking. Also they have a much wider surface area and should wear longer. I'm using 7/8 OD sleeves in the spindles, so they will fit right over those.  Made a quick jig to locate the upper ball joint while fabricating the upper arms. On this first arm, I didn't bother to clamp things as straight as I should have. It turned out ok, but not as true as the second one.  I left a bit of room for lock nuts on the threads of the hiem joints. I did some research and it seems most people think it's a bit hard on the threads to not use lock nuts, even if the hiems are used in a way that they can't turn. The threads are still most of the way through the weld in bung. This isn't the final adjustment here anyway, just a starting point.  To weld the next piece on, I clamped a flat bar across the top to hole them in line.  Starting the 2nd upper arm, I clamped and washered everything so that it was straight and level before welding it together. It turned out a lot nicer.   Completed both upper arms. Now with the lower joints figured out, I can start work on the lower ones next. Then I'll need to figure out the shock mounts. Should be interesting to see how the steering shaft will go.  | |

|

| |

CraftsmanQuad19

Veteran Member

2018 Build-Off Entrant

2018 Build-Off Entrant

2019 Build-Off Finalist

2019 Build-Off Finalist

Age : 24

Join date : 2016-04-12

Points : 5949

Posts : 2640

Location : Indiana

|  Subject: Re: Simplicity Broadmoor R/S Project Subject: Re: Simplicity Broadmoor R/S Project  February 17th 2020, 12:46 pm February 17th 2020, 12:46 pm | |

| Looks awesome dude. Just wondering if you’ve considered entering it in the buildoff? With the deadline you’ve set you should make it, and if you qualify for TTC I think you’d qualify for the buildoff too wouldn’t you? I don’t think you’re anywhere near 50% | |

|

| |

MightyRaze

Administrator

2017 Build-Off Finalist

2017 Build-Off Finalist

2018 Build-Off Top 3 Winner

2018 Build-Off Top 3 Winner

2019 Build-Off Top 3 Winner

2019 Build-Off Top 3 Winner

2021 Winner of Winners

2021 Winner of Winners

1st Place Build-Off 2022

1st Place Build-Off Winner 2022

10,000 POSTS!

10,000 POSTS!

2024 Build-Off Entrant

2024 Build-Off Entrant

Age : 49

Join date : 2016-09-06

Points : 15588

Posts : 10940

Location : Oklahoma

| |

| |

mr.modified

Veteran Member

2015 Build-Off Top 3 Winner

2015 Build-Off Top 3 Winner

2016 Build-Off Top 3 Winner

2016 Build-Off Top 3 Winner

2018 Build-Off Finalist

2018 Build-Off Finalist

2022 Build-Off Entrant

2022 Build-Off Entrant

1st Place Build-Off 2014

1st Place Build-Off Winner 2014

2023 Build-Off Entrant

2023 Build-Off Entrant

Age : 34

Join date : 2013-11-02

Points : 7137

Posts : 2907

Location : New Jersey USA

|  Subject: Re: Simplicity Broadmoor R/S Project Subject: Re: Simplicity Broadmoor R/S Project  February 17th 2020, 6:05 pm February 17th 2020, 6:05 pm | |

| Thanks! I thought about it but didn't know if I wanted to. I guess it really wouldn't be any extra effort since I'm still going to post the same updates ect. Originally I wanted to start on it before the build off started, but I really didn't get that far anyway. Mostly just figured out how I wanted to build it.

I suppose I might as well enter as long as you guys don't count what I already did as working on it ahead of time and all that. | |

|

| |

MightyRaze

Administrator

2017 Build-Off Finalist

2017 Build-Off Finalist

2018 Build-Off Top 3 Winner

2018 Build-Off Top 3 Winner

2019 Build-Off Top 3 Winner

2019 Build-Off Top 3 Winner

2021 Winner of Winners

2021 Winner of Winners

1st Place Build-Off 2022

1st Place Build-Off Winner 2022

10,000 POSTS!

10,000 POSTS!

2024 Build-Off Entrant

2024 Build-Off Entrant

Age : 49

Join date : 2016-09-06

Points : 15588

Posts : 10940

Location : Oklahoma

| |

| |

redzz02

Site VIP

2014 Build-Off Entrant

2014 Build-Off Entrant

2016 Build-Off Top 3 Winner

2016 Build-Off Top 3 Winner

2021 Winner of Winners

2021 Winner of Winners

1st Place Build-Off 2015

1st Place Winner Build-Off 2015

1st Place Build-Off 2017

1st Place Build-Off Winner 2017

1st Place Build-Off 2018

1st Place Build-Off Winner 2018

Age : 29

Join date : 2010-05-12

Points : 6349

Posts : 899

Location : PA pittsburgh and pymatuning

| |

| |

MightyRaze

Administrator

2017 Build-Off Finalist

2017 Build-Off Finalist

2018 Build-Off Top 3 Winner

2018 Build-Off Top 3 Winner

2019 Build-Off Top 3 Winner

2019 Build-Off Top 3 Winner

2021 Winner of Winners

2021 Winner of Winners

1st Place Build-Off 2022

1st Place Build-Off Winner 2022

10,000 POSTS!

10,000 POSTS!

2024 Build-Off Entrant

2024 Build-Off Entrant

Age : 49

Join date : 2016-09-06

Points : 15588

Posts : 10940

Location : Oklahoma

|  Subject: Re: Simplicity Broadmoor R/S Project Subject: Re: Simplicity Broadmoor R/S Project  February 17th 2020, 9:15 pm February 17th 2020, 9:15 pm | |

| - redzz02 wrote:

- @mr.modified well under 50% can we just move this thread to the build off section and add build off to the title? @MightyRaze

I can if he posts a picture for entry sign with some of his parts. What will probably happen at that point, is either A) If he posts it here, I will lock and split this topic and ad a link back and forth. B) If he starts a new thread in the entry forum, I will do the same. | |

|

| |

Doug

Site Owner

2014 Build-Off Entrant

2014 Build-Off Entrant

2017 Build-Off Entrant

2017 Build-Off Entrant

Age : 29

Join date : 2012-12-24

Points : 7752

Posts : 3044

Location : Lebanon County, PA

| |

| |

mr.modified

Veteran Member

2015 Build-Off Top 3 Winner

2015 Build-Off Top 3 Winner

2016 Build-Off Top 3 Winner

2016 Build-Off Top 3 Winner

2018 Build-Off Finalist

2018 Build-Off Finalist

2022 Build-Off Entrant

2022 Build-Off Entrant

1st Place Build-Off 2014

1st Place Build-Off Winner 2014

2023 Build-Off Entrant

2023 Build-Off Entrant

Age : 34

Join date : 2013-11-02

Points : 7137

Posts : 2907

Location : New Jersey USA

|  Subject: Re: Simplicity Broadmoor R/S Project Subject: Re: Simplicity Broadmoor R/S Project  February 17th 2020, 10:46 pm February 17th 2020, 10:46 pm | |

| Well JEEZ DOUG, no need to make me feel bad about how much work I have left.

But anyways, I printed out a build off entry sign. Guess I'll just start a new thread in the build off section tomorrow when parts and my 10 year old broken down cannon camera are in the same location. | |

|

| |

MightyRaze

Administrator

2017 Build-Off Finalist

2017 Build-Off Finalist

2018 Build-Off Top 3 Winner

2018 Build-Off Top 3 Winner

2019 Build-Off Top 3 Winner

2019 Build-Off Top 3 Winner

2021 Winner of Winners

2021 Winner of Winners

1st Place Build-Off 2022

1st Place Build-Off Winner 2022

10,000 POSTS!

10,000 POSTS!

2024 Build-Off Entrant

2024 Build-Off Entrant

Age : 49

Join date : 2016-09-06

Points : 15588

Posts : 10940

Location : Oklahoma

| |

| |

mr.modified

Veteran Member

2015 Build-Off Top 3 Winner

2015 Build-Off Top 3 Winner

2016 Build-Off Top 3 Winner

2016 Build-Off Top 3 Winner

2018 Build-Off Finalist

2018 Build-Off Finalist

2022 Build-Off Entrant

2022 Build-Off Entrant

1st Place Build-Off 2014

1st Place Build-Off Winner 2014

2023 Build-Off Entrant

2023 Build-Off Entrant

Age : 34

Join date : 2013-11-02

Points : 7137

Posts : 2907

Location : New Jersey USA

|  Subject: [2020 Build-Off Entry] Mr.Modified's Simplicity Broadmoor RS Subject: [2020 Build-Off Entry] Mr.Modified's Simplicity Broadmoor RS  February 18th 2020, 12:01 pm February 18th 2020, 12:01 pm | |

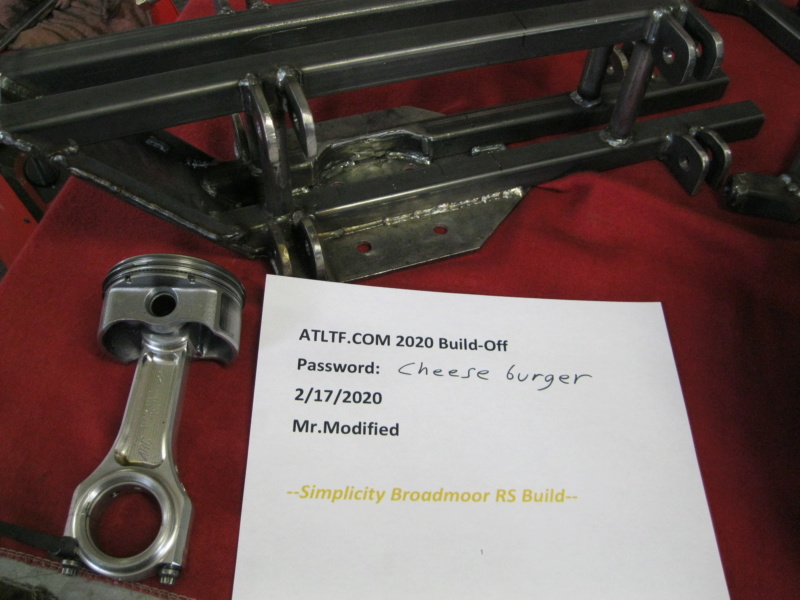

| The plan is to build a machine with better handling than the traditional off road tractor layout. By custom building a frame, I hope to lower the center of gravity by reducing wasted space and also add front and rear suspension. The body work will be based off the 1970's Simplicity Broadmoors. Specs as planned. Subject to changes as nessesary...The Engine: Briggs Opposed twin (Horizontal shaft) with ARC rods and flywheel ect. Transmission: 633a Tire size: 18 x 8.50 x 10 Kenda Terra Trac Body work: Fiberglass Suspension Front: IFS, Coil over shocks, 3" travel Suspension Rear: Straight axle hinged on transmission axle stubs, Coil over shocks, 3" travel Drive: 5/8" belt clutch with chain final to rear axle Brakes: Rear axle disk Some work has already been completed, as you already know if you saw my other build thread. I have the front section of the frame mostly built and started work on the suspension arms. Other than that, I've just collected parts. I have five opposed twins in various states. A couple stock ones and a few with billet parts. Some suspension joints and a golf cart rack and pinion have been purchased along with some alloy wheels from northern tool. Front frame section, Upper control arms, yamaha golf cart rack and pinion, ARC billet rod, and Northern tool golf cart wheel.   Lots of options are available for 4 on 4 hubs/lug pattern, which was one reason I went with golf cart wheels. I also wanted to keep the wheel size small enough that the rear suspension would have room to move with a low seating position. The outter tire diameter isn't much less than the front wheels on the Simplicity Adventure Edition, so hopefully they will do alright on rocks ect.  Approved MightyRaze Feb 18, 2020 Approved MightyRaze Feb 18, 2020[adm]While the build actually started before build-off, it still meets the less than 50% rule of complete by build-off start. Per rule on entry instructions: https://www.atltf.com/t5969-2020-build-off-instructions4.) In your thread, post the picture(s) and a description outlining your build plans. Remember that your project must be LESS than 50% finished to qualify, so you need to convince us you have a lot of work ahead. Make it count!As @Doug has stated when he personally saw the project, @mr.modified still has a lot of work ahead of him. Previous work on the project can be found here: https://www.atltf.com/t6224-simplicity-broadmoor-r-s-project[/adm]

Last edited by mr.modified on March 29th 2020, 11:45 am; edited 1 time in total | |

|

| |

MightyRaze

Administrator

2017 Build-Off Finalist

2017 Build-Off Finalist

2018 Build-Off Top 3 Winner

2018 Build-Off Top 3 Winner

2019 Build-Off Top 3 Winner

2019 Build-Off Top 3 Winner

2021 Winner of Winners

2021 Winner of Winners

1st Place Build-Off 2022

1st Place Build-Off Winner 2022

10,000 POSTS!

10,000 POSTS!

2024 Build-Off Entrant

2024 Build-Off Entrant

Age : 49

Join date : 2016-09-06

Points : 15588

Posts : 10940

Location : Oklahoma

| |

| |

MightyRaze

Administrator

2017 Build-Off Finalist

2017 Build-Off Finalist

2018 Build-Off Top 3 Winner

2018 Build-Off Top 3 Winner

2019 Build-Off Top 3 Winner

2019 Build-Off Top 3 Winner

2021 Winner of Winners

2021 Winner of Winners

1st Place Build-Off 2022

1st Place Build-Off Winner 2022

10,000 POSTS!

10,000 POSTS!

2024 Build-Off Entrant

2024 Build-Off Entrant

Age : 49

Join date : 2016-09-06

Points : 15588

Posts : 10940

Location : Oklahoma

| |

| |

mr.modified

Veteran Member

2015 Build-Off Top 3 Winner

2015 Build-Off Top 3 Winner

2016 Build-Off Top 3 Winner

2016 Build-Off Top 3 Winner

2018 Build-Off Finalist

2018 Build-Off Finalist

2022 Build-Off Entrant

2022 Build-Off Entrant

1st Place Build-Off 2014

1st Place Build-Off Winner 2014

2023 Build-Off Entrant

2023 Build-Off Entrant

Age : 34

Join date : 2013-11-02

Points : 7137

Posts : 2907

Location : New Jersey USA

| |

| |

mr.modified

Veteran Member

2015 Build-Off Top 3 Winner

2015 Build-Off Top 3 Winner

2016 Build-Off Top 3 Winner

2016 Build-Off Top 3 Winner

2018 Build-Off Finalist

2018 Build-Off Finalist

2022 Build-Off Entrant

2022 Build-Off Entrant

1st Place Build-Off 2014

1st Place Build-Off Winner 2014

2023 Build-Off Entrant

2023 Build-Off Entrant

Age : 34

Join date : 2013-11-02

Points : 7137

Posts : 2907

Location : New Jersey USA

|  Subject: Re: Simplicity Broadmoor R/S Project Subject: Re: Simplicity Broadmoor R/S Project  February 18th 2020, 9:21 pm February 18th 2020, 9:21 pm | |

| Tonight I didn't get really far, but avoided a potentially serious time wasting mistake. Previously I had roughly measured the angle of the king pins and thought there was a 1" difference between the upper and lower mounting points (when the wheel is straight up and down). As it turns out, it's only a 3/8" difference. To keep the wheels fairly straight, I need to make the lower arms longer than the top to account for the angle. Would have had some serious camber if I made them a full 1" longer... Forward frame is flipped upside down and the "jig" is clamped in the new revised position for the lower control arms. I will double check tomorrow night before continuing. A minor difference is the thickness of the skid plate is now added in between the jig and frame. To be able to clamp the arm pieces straight during welding I will add a couple big washers at the ball joint end (bolt end of the jig) to account for it.  Also realized that Haspin is only about four months away. I've gotta really step things up to be anywhere close to done by then. I'll have a bit more time before the Top Tractor Challenge, but it would be best to be done for Haspin so I can do some testing and also fine tuning before the event in August. Besides that, I'd need to have some seat time on the thing to have a good feel for it. | |

|

| |

Sponsored content

| |

| |

| | Simplicity Broadmoor R/S Project |  |

|