| | | Vari drive with 5 speed transaxle |  |

|

+12biggasmowers Double W Cross Ranch Crazy_Carl mr.modified AllisKidD21 TheBeal Lawren Wimberly tater195 RichieRichOverdrive MightyRaze MatthewD prancstaman 16 posters | |

| Author | Message |

|---|

prancstaman

Veteran Member

Join date : 2015-02-02

Posts : 1412

|  Subject: No more busted knuckles!!! Subject: No more busted knuckles!!!  June 10th 2018, 11:35 pm June 10th 2018, 11:35 pm | |

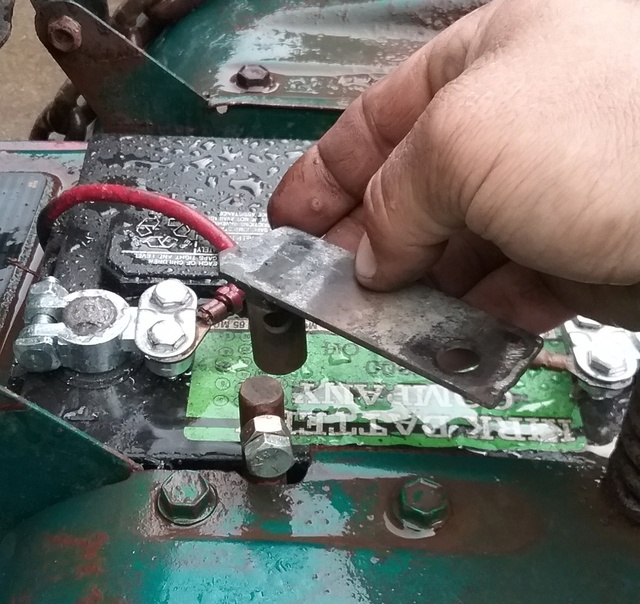

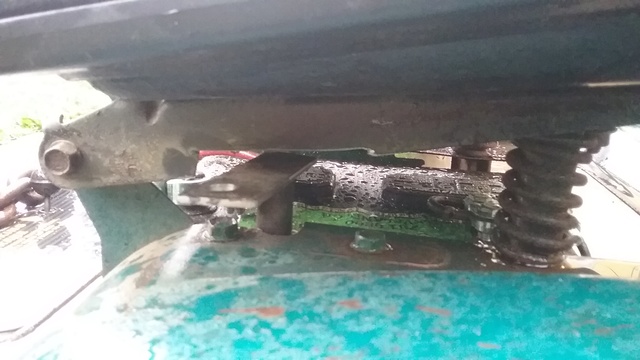

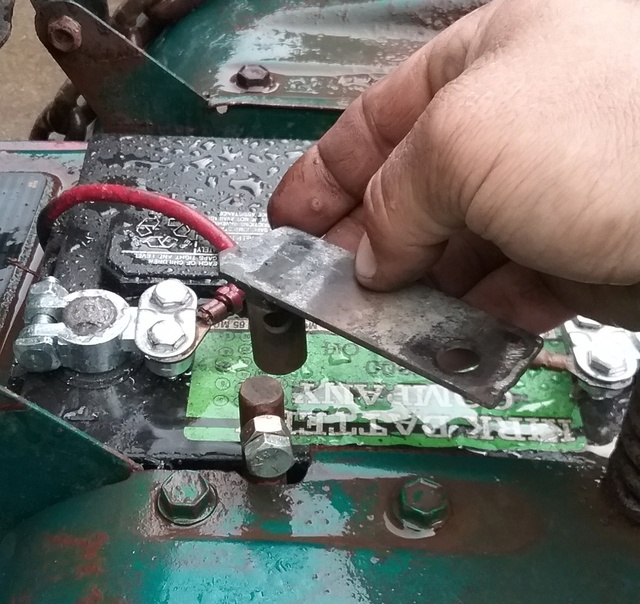

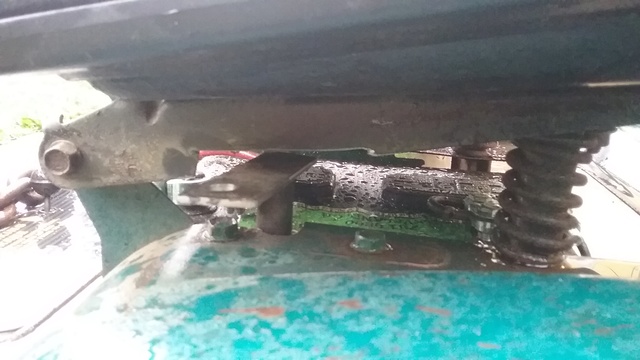

| Hay People, I finally got the shifter made. No more busted knuckles for me, LOL. And was easier then I thought it would be to make something workable, I actually been dreading making a shifter because I thought it would be hard. K.I.S.S method applied and approved. An added benefit of having a steel dash is you can weld to it. So on the side of the dash I welded a spacer to it for a pivot point. Then drilled the hole for the bolt inside the spacer.  Next was the arm for the shifter rod on the transaxle. I drilled out a piece of pipe to slide over the shifter rod then marked and drilled a hole for a bolt to go through and lock the pipe onto the shifter rod. Then welded a flat piece on top for the linkage to attach to after I figured out range of motion.  Made a shifter. Some deck linkage I found in the pile of mower parts. Bent it up to contour the dash and hold the linkage rod. Welded a spacer to the pivot point so it doesn't rock on the bolt and welded on a handle.  Found a long heavy rod for the linkage with one end having an adjuster on it so I can adjust where the shifter stops, mainly when the shifter is all the way forward (which is reverse gear). The other end I welded a bolt to for ease of removal and used a nylock nut on it.  I had to clearance the seat bracket some more for the shifter lever for the transaxle.  Finally pieced it together. The linkage rod is out of the way which was unexpected and good. The shifter is in reverse now. I'll paint it black later, it was raining when I was making this.  I shaped the shifter to contour the dash so it looks nice.  And this is the shifter in 5th gear on the transaxle.  I haven't even tested it yet so I have no clue if it will hold up without bending. Pushing forward and pulling backwards, the shifter should hold up. But the shifter is easy to bend side ways because it is only 1/16 inch thick steel. Should be simple to reinforce it later or make a shifter out of something thicker and stronger later. I'm still having a problem shifting the transaxle from gear to gear. I'm thinking that not having a way to release the pressure on the trans belt is making it shift hard because even though I have the clutch pushed in that only releases the engine belt pressure while the trans belt is still under tension. That makes the shifting forks not want to move in the transaxle. It's mainly hard to shift in reverse, neutral, and first gear on the transaxle. 2nd through 5th are always easy because I'm moving and there is no big pressure on the shift forks. Looks like I'll have to add a second clutch and have it going to the trans belt tensioner so I can shift into 1st, neutral, and reverse. Maybe have it on the shifter handle for the transaxle. Should be easy by hand since there are small springs on the trans belt tensioner. | |

|   | | AllisKidD21

Moderator

2020 Build-Off Entrant

2020 Build-Off Entrant

1st Place Build-Off 2019

1st Place Build-Off Winner 2019

Age : 25

Join date : 2016-07-10

Points : 8378

Posts : 5190

Location : Ontario Canada

|  Subject: Re: Vari drive with 5 speed transaxle Subject: Re: Vari drive with 5 speed transaxle  June 10th 2018, 11:45 pm June 10th 2018, 11:45 pm | |

| I LOVE that shifter setup! Looks super cool, really clean and almost factory looking. Should be much more comfortable to use. Also like you said it'd be pretty simple to reinforce that shifter handle if it started to bend too.  "This'll either wake you up or put you to sleep forever!"- Red Green "Whatever you do you should do right, even if it's something wrong." - Hank Hill - MTD Off-Road Build

- Ford LT 110 Off-Road Build

- Craftsman GT 6000 Off-Road Build

- Sears LT11 Rat Rod Build *2019 Build-Off Winner!* Garden Tractor Collection: Allis B-110 x2, 710, 716, & 410 - Wheel Horse 655, 953 & 500 Special - Case 444 - Bolens Versamatic, G10 & 1668 Diesel Swapped - Cub 106, 124 & 1000/149 Frankentractor - Ford 120, LGT 125 & 145 - White 1650 Yard Boss - Moto Mower 710-100 | |

|   | | prancstaman

Veteran Member

Join date : 2015-02-02

Points : 4887

Posts : 1412

Location : Cleveland,Ohio

|  Subject: Re: Vari drive with 5 speed transaxle Subject: Re: Vari drive with 5 speed transaxle  June 11th 2018, 12:42 am June 11th 2018, 12:42 am | |

| Thank you. Yes, more comfortable!! I was planning on 1/4 inch rod stock welded to the inside of the shifter, the whole length of it, if need be. I forgot to mention in the post that I still need to make a pointer somehow, to show what gear the transaxle is in. Maybe a Z gate for the shifter to follow, since it is a little bendable sideways and would spring back without staying bent would seem fitting. But that might be a while. I only had a chance to work on this because it was raining and I did the work in the rain. | |

|   | | MatthewD

Veteran Member

2015 Build-Off Entrant

2015 Build-Off Entrant

2016 Build-Off Entrant

2016 Build-Off Entrant

Age : 22

Join date : 2014-11-16

Points : 5544

Posts : 1993

Location : Northern Ireland

| |   | | prancstaman

Veteran Member

Join date : 2015-02-02

Points : 4887

Posts : 1412

Location : Cleveland,Ohio

|  Subject: Re: Vari drive with 5 speed transaxle Subject: Re: Vari drive with 5 speed transaxle  June 11th 2018, 9:13 pm June 11th 2018, 9:13 pm | |

| - MatthewD wrote:

- Nice work on the shifter! The linkage looks like it should stay out of the way of your leg which is good.

Thanks Matt. I kept the linkage on the inside of the shifter just for that. Everything seem to fit together without that much work. Took about 3 or so hours during the day while doing other stuff too. I haven't even sat on the mower yet to try it out, been too busy lately. I did this Sunday and tried to finish to where I could cut some grass but other things happened like running erins and such, Oh well, atleast I got it done.  | |

|   | | Crazy_Carl

Veteran Member

2018 Build-Off Entrant

2018 Build-Off Entrant

2024 Build-Off Entrant

2024 Build-Off Entrant

Age : 35

Join date : 2017-10-30

Points : 5124

Posts : 2561

Location : Rochester, New York

|  Subject: Re: Vari drive with 5 speed transaxle Subject: Re: Vari drive with 5 speed transaxle  June 11th 2018, 9:53 pm June 11th 2018, 9:53 pm | |

| Have you tried removing the belt going to the trans to see if it still shifts hard? I don't understand the pressure of the shift forks. If the tension were off that belt maybe the input shaft can wiggle just a little bit to allow the shift keys to move more easily back and forth?

I really like this column shift concept. It should be easily to strengthen and refine it. | |

|   | | prancstaman

Veteran Member

Join date : 2015-02-02

Points : 4887

Posts : 1412

Location : Cleveland,Ohio

|  Subject: Re: Vari drive with 5 speed transaxle Subject: Re: Vari drive with 5 speed transaxle  June 13th 2018, 1:06 am June 13th 2018, 1:06 am | |

| - Crazy_Carl wrote:

- Have you tried removing the belt going to the trans to see if it still shifts hard? I don't understand the pressure of the shift forks. If the tension were off that belt maybe the input shaft can wiggle just a little bit to allow the shift keys to move more easily back and forth?

I really like this column shift concept. It should be easily to strengthen and refine it. Well, how I came to the conclusion about the shift forks is- when the mower is sitting on level ground, it can move back and forth a little while in gear and engine off (driveline slop), this is when it shifts ok in reverse to neutral to 1st gear. It also shifts ok into these gears while engine running and on level ground with clutch pushed in and the driveline relaxed. Now when I had it on level ground with the engine off and in reverse and would push it backwards to create pressure on the driveline then I would not be able to shift into another gear like neutral, then stop pushing on the mower then I would be able to shift. The trans was ok when I took it apart so the conclusion for the not shifting right would be because of driveline tension. Driveline tension would be defined for the transaxle as- when the transaxle input wants to turn but is held back by the output axles not moving. When this happens the slop in the transaxle is gone because of the pressure wanting to turn the input. All those clearances in between the gears are gone because they want to turn but can't, in other words. So when this happens it makes the internal parts hard to slide sideways like the shift forks which slide sideways to pick the gear. Now the shift forks slide sideways because there is space for the forks to slide sideways to pick the gear (clearance), but if the gear wants to turn and can't because the input wants to turn and can't, this takes away the sliding clearance around the shift fork which is actually jammed up from the pressure (driveline tension). So my theory of this gearbox is- when it was in a regular riding mower it worked fine shifting because when you pushed the clutch in it released the pressure on the input shaft so it can spin freely which released the driveline tension in the transaxle which opened up the clearances for the shift forks to move to the selected gear. My setup does this kinda which is why it is possible to shift while it is sitting on flat ground and no driveline tension. But when I am riding and am on a hill or drove into a tree I can't shift even with the clutch pushed in because the trans belt still has tension on it from the trans belt tensioner, but if I rock the back to lift one rear tire so it can spin free to remove this tension then I can shift. The key was always to lift one rear tire to spin free to remove this built up tension to be able to shift. So if I am able to free up the trans belt tensioner with a clutch lever to releave the driveline pressure in the transaxle this way then it should shift then. | |

|   | | Crazy_Carl

Veteran Member

2018 Build-Off Entrant

2018 Build-Off Entrant

2024 Build-Off Entrant

2024 Build-Off Entrant

Age : 35

Join date : 2017-10-30

Points : 5124

Posts : 2561

Location : Rochester, New York

|  Subject: Re: Vari drive with 5 speed transaxle Subject: Re: Vari drive with 5 speed transaxle  June 13th 2018, 11:16 am June 13th 2018, 11:16 am | |

| Makes sense to me.

This reminds me of my buddy's MTD mower he had with varidrive and F-N-R. The thing was a pain in the butt to shift into reverse on hills. | |

|   | | prancstaman

Veteran Member

Join date : 2015-02-02

Points : 4887

Posts : 1412

Location : Cleveland,Ohio

|  Subject: Little update Subject: Little update  October 14th 2018, 7:34 pm October 14th 2018, 7:34 pm | |

| Hay People, Getting towards the end of the season, getting cold and just a few more times of using this mower this year. I really just had one big issue that I took care of today so far. I just had to tighten the bolt on the transaxle shifter rod I made for the linkage going to the dash shifter. Plus adjusted the dash shifter for that too because it was hitting the dash before it would go into reverse.  Other then that, this thing just keeps running and running. I'll be using it for a couple hours each time and is set at full throttle the hole time. Doesn't miss a beat. Pretty much it for now. | |

|   | | AllisKidD21

Moderator

2020 Build-Off Entrant

2020 Build-Off Entrant

1st Place Build-Off 2019

1st Place Build-Off Winner 2019

Age : 25

Join date : 2016-07-10

Points : 8378

Posts : 5190

Location : Ontario Canada

|  Subject: Re: Vari drive with 5 speed transaxle Subject: Re: Vari drive with 5 speed transaxle  October 14th 2018, 7:47 pm October 14th 2018, 7:47 pm | |

| Nice to see this rig still working good! It'd be cool to see some videos of it in action on your channel.  "This'll either wake you up or put you to sleep forever!"- Red Green "Whatever you do you should do right, even if it's something wrong." - Hank Hill - MTD Off-Road Build

- Ford LT 110 Off-Road Build

- Craftsman GT 6000 Off-Road Build

- Sears LT11 Rat Rod Build *2019 Build-Off Winner!* Garden Tractor Collection: Allis B-110 x2, 710, 716, & 410 - Wheel Horse 655, 953 & 500 Special - Case 444 - Bolens Versamatic, G10 & 1668 Diesel Swapped - Cub 106, 124 & 1000/149 Frankentractor - Ford 120, LGT 125 & 145 - White 1650 Yard Boss - Moto Mower 710-100 | |

|   | | prancstaman

Veteran Member

Join date : 2015-02-02

Points : 4887

Posts : 1412

Location : Cleveland,Ohio

|  Subject: Re: Vari drive with 5 speed transaxle Subject: Re: Vari drive with 5 speed transaxle  October 15th 2018, 12:11 am October 15th 2018, 12:11 am | |

| Works real good still. I'd like to do something on my channel too, been busy working on my cars and other peoples cars that I have no time. But I see some spare time coming up though to do something, maybe. | |

|   | | prancstaman

Veteran Member

Join date : 2015-02-02

Points : 4887

Posts : 1412

Location : Cleveland,Ohio

|  Subject: Re: Vari drive with 5 speed transaxle Subject: Re: Vari drive with 5 speed transaxle  November 22nd 2018, 10:04 pm November 22nd 2018, 10:04 pm | |

| Hay People,

Well, it's the end of the season, no more cutting the grass, thank goodness, LOL. I packed it up for the winter and pulled the battery so hopefully the battery don't die sitting in my basement for next year. This thing was running pretty good for the most part. Last thing I did was the shifter adjustment, probably because the linkage bent a little, still have the issue of the transaxle not shifting when under a load. I expected that which is why I made the linkage adjustable. A next year fix, definitely, because the issue is getting old real quick, I'm thinking a clutch lever on the shifter handle should do it.

Still need a front bumper and mount some new lights on it too. The belts held up great for the vari drive. And the deck belt needs to be adjusted so I can turn the blades off on the deck, would be nice and be easier to start and idle too with the blades off. It starts and idles fine now as is, but still. Worry about painting this way later because I need to pull it all apart and want to do a good job painting it since I got all the gear for that.

Well, that should be it for this project for this year, till next cutting season when I pull it out again and start using it. | |

|   | | prancstaman

Veteran Member

Join date : 2015-02-02

Points : 4887

Posts : 1412

Location : Cleveland,Ohio

|  Subject: A new season begins! Subject: A new season begins!  April 28th 2019, 12:15 am April 28th 2019, 12:15 am | |

| Hay People, That time of the season again, LOL. Yup, I got around to pulling this thing out of storage, (covered in a plastic tarp and shoved up under my Jeep hood). Looked it over real quick. Seemed good. Only one flat tire, the rear left one, LOL. Nothing was froze up rusted or anything like that.  I kept the battery in my basement all winter. Not the best place to store a battery but seemed ok at that moment. Threw in the battery. Forgot how tight of a fit it was. After struggling with the wires from under it it feel in. Put on the battery ends. I should replace the negative battery terminal because it is cracked but this will do for now. I dought it even draws 100 amps to start this thing. And everything is cleaned and snugged up.  I then pull out the dipstick. You would think that this motor has been sitting for atleast 5 months untouched that when I pull out the dipstick you would get an exact reading of how much oil is in the motor. Nope!! The red arrow is the reading and the light blue arrow is where it's suppose to be. For some reason beyond my state of thinking, got a false reading on the dipstick. Atleast there is oil in it, LOL. Sniffed it to make sure there is no gas in it, NOPE!! Shoved it back in and moved on.  Was a 1/4 tank of gas left in it over winter. Oops. I grab the gas can and top it off. Hopped on, locked the clutch, made sure the deck was up, turned the gas on, waited about 10 seconds, and turned the key, LOL. Waw, waw, waw, Vroom, LOL. After 3 strokes, it started right up. Love me a flattie, LOL. I know, headlights.  Let it run for a minute or two. Put it in gear, low/low, it doesn't move. No sweat, I try 3/low, and it moves. Shift linkage was stuck from rust. Shifted it up and down on the vari drive to free things up. Try low/low again and it works, cool. Drop the blades and cut the grass. Worked great. No big issues to complain about. I tried the higher gears on the vari drive just for kicks. Doesn't seem to be going into the higher gears too good. Plus switches gears very slow too. I finish cutting the grass for now. I pretty much just threw the battery in, checked the oil, filled the tires, gassed it up, and started it. Not to bad. Very reliable for the most part. I got done what needed to be done for right now, and I'm happy. After cutting the grass, before I turned it off, I wanted to check the vari drive. I put the transaxle in neutral so the belts can spin while out of gear. Pull off the tunnel cover to see the belts. Put the vari drive in first and pop the clutch. It spins fine. While it is spinning I drop the shifter in 7th and everything changes like it should, all the way to 7th gear but seemed slow.   That will be my first fix. Making sure I get all the gears and it changes gears faster on the vari drive. This is the spring for the clutch pedal. Need to pull it tighter. I been thinking about it and I think I can use a piece of threaded rod to make an adjuster for this spring to pull it tighter. Should shift faster and will make sure I get all the gears on the vari drive. Next will be a second clutch for the trans belt. So when there is tension on the driveline, hit this second clutch to release the tension and be able to shift gears on the transaxle with no problems, well I hope anyways. Next will be the headlights. I bought a set of cheap LED's from Walmart but they are the long skinny ones and won't fit in the round holes, LOL. I can make them fit but won't look right. So I'll just buy another set, round ones this time. Readjust the deck belt so the blades turn off and I can idle the engine. My to do list for now.  Later | |

|   | | Crazy_Carl

Veteran Member

2018 Build-Off Entrant

2018 Build-Off Entrant

2024 Build-Off Entrant

2024 Build-Off Entrant

Age : 35

Join date : 2017-10-30

Points : 5124

Posts : 2561

Location : Rochester, New York

|  Subject: Re: Vari drive with 5 speed transaxle Subject: Re: Vari drive with 5 speed transaxle  April 28th 2019, 11:36 am April 28th 2019, 11:36 am | |

| You'll love LED headlights.

I'm pretty sure I'm seeing a couple rusted out holes in your deck. What kind of shape is the rest of the deck in? | |

|   | | prancstaman

Veteran Member

Join date : 2015-02-02

Points : 4887

Posts : 1412

Location : Cleveland,Ohio

|  Subject: Re: Vari drive with 5 speed transaxle Subject: Re: Vari drive with 5 speed transaxle  April 28th 2019, 7:03 pm April 28th 2019, 7:03 pm | |

| Yup, those are holes Carl. I just noticed them too. Should be the worst of it in the pic. I pieced this deck together a year or 2 ago. Everything was used when I put it together but good. I think I went as far as taking the bearings out of the spindles to regrease them and put it back together. I need to find the original blades for this deck because the blades on it now are a couple inches smaller and leaves a line of grass uncut in the middle, LOL. Very annoying. Need to level the deck too. A bunch of little things to do still. But it works. | |

|   | | Murraymountain

Veteran Member

2019 Build-Off Finalist

2019 Build-Off Finalist

2020 Build-Off Entrant

2020 Build-Off Entrant

2022 Build-Off Entrant

2022 Build-Off Entrant

Join date : 2019-02-04

Points : 4212

Posts : 2167

Location : North Carolina

|  Subject: Re: Vari drive with 5 speed transaxle Subject: Re: Vari drive with 5 speed transaxle  April 28th 2019, 8:36 pm April 28th 2019, 8:36 pm | |

| Did you cut out a bigger space for the battery? I know that allot of those MTDs had "less than average" battery space.

Yeah, a little rust ain't gonna hurt nothin'. | |

|   | | prancstaman

Veteran Member

Join date : 2015-02-02

Points : 4887

Posts : 1412

Location : Cleveland,Ohio

|  Subject: Re: Vari drive with 5 speed transaxle Subject: Re: Vari drive with 5 speed transaxle  April 28th 2019, 8:43 pm April 28th 2019, 8:43 pm | |

| Yes. I cut out alot for the car battery to fit in there. I think when I did it, I cut out the most I could. Any more and I think I would have to relocate the shifter for the transaxle. I did the mod on page 5, in the middle of the page. Fits in there pretty tight. The battery is out of my Ford Escort. The original battery was like half the size, if not smaller. | |

|   | | prancstaman

Veteran Member

Join date : 2015-02-02

Points : 4887

Posts : 1412

Location : Cleveland,Ohio

|  Subject: It broke!! Subject: It broke!!  June 21st 2019, 9:29 pm June 21st 2019, 9:29 pm | |

| Hay People, I finally broke the damn thing!! LOL. I guess i hit too many tree trunks, or driveway curbs, or fence posts, or something like that because the steering arm on the axle that the rod from the column goes to broke in half. I figured the original axle had the piece I needed to fix it so I went diggin, found it at the bottom of the pile (figures). That's the original axle laying by the tire and broken linkage on the tire.  Better pic of the broke piece.  It broke a couple days ago cutting the grass. Been raining since then and today was sunny. Took no time to fix. I pulled the piece off the original axle and was going to weld some kind of bracket on it to make it stronger but the factory already did it. Cool.  Ready for more cutting.  | |

|   | | Murraymountain

Veteran Member

2019 Build-Off Finalist

2019 Build-Off Finalist

2020 Build-Off Entrant

2020 Build-Off Entrant

2022 Build-Off Entrant

2022 Build-Off Entrant

Join date : 2019-02-04

Points : 4212

Posts : 2167

Location : North Carolina

|  Subject: Re: Vari drive with 5 speed transaxle Subject: Re: Vari drive with 5 speed transaxle  June 22nd 2019, 9:40 am June 22nd 2019, 9:40 am | |

| Oh yeah those MTD axles are junk. I just replaced the one in the Lowes and it's worn out again. I think it's that brackets fault. | |

|   | | prancstaman

Veteran Member

Join date : 2015-02-02

Points : 4887

Posts : 1412

Location : Cleveland,Ohio

|  Subject: I broke it again Subject: I broke it again  August 8th 2019, 8:46 pm August 8th 2019, 8:46 pm | |

| Well People,

She is down again. I was cutting over a section in my yard where I cut up a tree and a big stick jammed in on top of the deck. Locked the belt, a lot of smoke so I shut it off. I checked the blades to see if they was still spinning, yup. Restarted it, more smoke, turned it off. Had a closer look, found the stick, it was huge, LOL. Pulled it out, and the belt popped off on the restart. Didn't have it in me to put the belt back on to finish the yard, so screw it. There's tomorrow to fix it, LOL. Long day today for me.

So, was planning on fixing other stuff too while riding it anyways. Belt looked OK'ish, Ill reuse it for now. Kevlar stinks when it is frying on the pulley, LOL. I'll spend money on new blades. You are not suppose to deck concrete and bricks with them, by the way. You would think that would be an easy way to sharpen them but nope! They are not suppose to mulch up wood, like 2x4'ish sticks either. I looked under the deck a few weeks ago to see why the middle of the deck is not cutting, thinking I got the wrong blades, nope! The blades are curled up and around on the ends like those blow through party favors with the annoying whistles. Also smokes when you shut the motor off, a sign of getting hot, should top off the oil too. That's my fault there. Readjust the deck, so it cuts flat, even, and stops spinning when not engaged, would be very nice to have, LOL.

Yup, Later. | |

|   | | prancstaman

Veteran Member

Join date : 2015-02-02

Points : 4887

Posts : 1412

Location : Cleveland,Ohio

|  Subject: A plan, well kinda Subject: A plan, well kinda  August 10th 2019, 10:34 pm August 10th 2019, 10:34 pm | |

| Hay People, So, lookin at the damage, I popped of a blade on the deck to take with me, was a good idea, and seen the 6 point star was stripping because the nut came loose. Barely tightens right but does. No one had the blades. Looks like I got to come up with another plan. Belt won't stay on either, probably from frying, so tomorrow I'm getting another belt, great. I'll hold off on the blades for now. Too many issues with the deck like not turning off, crammed in there because of the transaxle, no guards for the belt, and starting to rust out. I can fix it all but... I got like 8 riding mowers laying around the yard. Some for projects and some for just parts. I got this Craftsman GT 6000 free from a guy from work. He asked if I wanted it. He didn't say what it was but that it was big. This thing is a monster, and loaded with features. He rebuilt the motor in it and would not start afterwards and he got tired of trying to make it run, LOL. Check it out. Been sitting in the sticks for a while.  Motor is a 22 hp Kohler, I'll be using that for another project. Never realized how big those motors were till now, COOL!  Never planned on getting it running again. Looks like a money pit to me. Got the plow for it too, will be used for the 4x4 riding mower. Has the Hi/Lo 6 speed, put into storage for now. Cast iron front axle, will be used. Will be using the deck too, 50 inch cut 3 bladed deck, which is solid but most of the bearings are seized on it from sitting. Has a tilt hood, I'll be using the bracket that does that for mine. Got a big muffler that is still solid I'll be using. Blade engagement seems to be electric, maybe use that depending on how complex it is, would be cool to have though. No clue on what else I can use but will be saving every nut and bolt too. As for the motor smoking when shutting off, I think it looks like it is doing it constantly. Must have fried the rings in the flattie somehow. Don't think it was the oil being low because it was just below the full mark. I think I just overheated it. I'll pull the tins off to see if air is flowing through. I think that is it for now, LOL. Later. | |

|   | | AllisKidD21

Moderator

2020 Build-Off Entrant

2020 Build-Off Entrant

1st Place Build-Off 2019

1st Place Build-Off Winner 2019

Age : 25

Join date : 2016-07-10

Points : 8378

Posts : 5190

Location : Ontario Canada

|  Subject: Re: Vari drive with 5 speed transaxle Subject: Re: Vari drive with 5 speed transaxle  August 10th 2019, 11:32 pm August 10th 2019, 11:32 pm | |

| That GT looks like it'd be a perfect grass cutter/yard worker! If you can get 'er cleaned up and working good I bet it would be a real nice machine.  "This'll either wake you up or put you to sleep forever!"- Red Green "Whatever you do you should do right, even if it's something wrong." - Hank Hill - MTD Off-Road Build

- Ford LT 110 Off-Road Build

- Craftsman GT 6000 Off-Road Build

- Sears LT11 Rat Rod Build *2019 Build-Off Winner!* Garden Tractor Collection: Allis B-110 x2, 710, 716, & 410 - Wheel Horse 655, 953 & 500 Special - Case 444 - Bolens Versamatic, G10 & 1668 Diesel Swapped - Cub 106, 124 & 1000/149 Frankentractor - Ford 120, LGT 125 & 145 - White 1650 Yard Boss - Moto Mower 710-100 | |

|   | | Murraymountain

Veteran Member

2019 Build-Off Finalist

2019 Build-Off Finalist

2020 Build-Off Entrant

2020 Build-Off Entrant

2022 Build-Off Entrant

2022 Build-Off Entrant

Join date : 2019-02-04

Points : 4212

Posts : 2167

Location : North Carolina

|  Subject: Re: Vari drive with 5 speed transaxle Subject: Re: Vari drive with 5 speed transaxle  August 11th 2019, 9:04 am August 11th 2019, 9:04 am | |

| Hey! That's a nice GT! I'd save it for sure. Easily worth $600.

I've heard how the 'deck pulley guards' help the blades disengage. May wanna try putting those on. And if you belt is fried, than definitely replace it, that caused bad vibration on my MTD. And another thing, does your belt ever slip (before it was fried of course)? I know the mounting points wear out on these MTD's and you have to replace EVERY mounting bracket on the tractor to fix belt slippage. Had to replace the deck on my brothers MTD. | |

|   | | prancstaman

Veteran Member

Join date : 2015-02-02

Points : 4887

Posts : 1412

Location : Cleveland,Ohio

|  Subject: Re: Vari drive with 5 speed transaxle Subject: Re: Vari drive with 5 speed transaxle  August 11th 2019, 11:01 pm August 11th 2019, 11:01 pm | |

| @AllisKidD21 It would do the job quite nicely but too far gone for me. Been sitting in the weather for 2 years straight. Everything is seized and would have to take it all apart to fix it. I could fix it but too busy doing other stuff. And the money spent would total up to buying a brand new smaller one that would be more reliable. @Murraymountain Nah, the GT is too far gone for me to fix quick and use. No time to do it. I figure about $700 in parts to get it going. Stuffs missing too, engine shroud and all ignition. Needs all belts, tires, deck rebuilt, and so. The MTD, the belt guards are long gone, LOL. If the deck is pulled up all the way there are brakes that the pulleys hit to stop the blades though. I just need to readjust the deck to get them to work but usually no time to. The guards on mine double as belt retainers but the belt stays on ok without them. Haven't needed to remake that part yet. Right now, the belt keep popping off the engine pulley. The Kevlar was burnt in spots with one little cut. I think that cut was popping it off when the blades was engaged because of the belt misalignment when the deck is dropped. Plus it was a 5/8 belt that didn't fit in the groove all the way. I went to Tractor Supply today with belt in hand. The 5/8" belts, measured them up, they was out of the size I needed ofcourse. So I looked in the 1/2" belts, They was out of the size I needed in that too. The next size up in the 1/2" belts I bought. Was real close too. Got home and put it together, guess what, too big. I could run back there and get another belt or make this one work, I figured I could make this one work but will take some doing. The adjustments on the deck was so far out of wack that I couldn't adjust the linkage to make the belt work because it was hitting the transaxle when I dropped the deck. It's a tight fit to begin with because the transaxle is further forward in the frame then the original f/n/r transaxle. That is the problem. Plus, the adjustments to move the deck forward when dropped is about an inch or two. Small window to make it work and just the right belt worked last time. Running back and forth to the store is just not doable right now. So I came up with another plan. I'll keep this 1/2" belt and make it work buy putting an adjustable fixed idler in the works. The span from spindle to spindle is open enough to fit a fixed idler it there. That way I have the choice of using a few more belt sizes when needed. Here is the setup I came up with. I welded a scrap piece of steel to connect the deck brackets together but can still unbolt the deck brackets and put them on another deck when needed. Welded a bolt on the scrap steel for a pivot. Made an idler arm and mounted a pulley on it. The arm can swing for adjustment. I drilled holes to the scrap steel so I can tie the idler arm in place. Pic of mockup.  I put it together. Tie up the idler pulley. Then tried it, worked like a charm! I now can use a couple size belts that can be bigger in size. There is a lot of adjustment there too, I can now use a belt that is way bigger then what is called for now, cool. Pic is of the setup in the mower with the engine running, deck dropped and working. Note how the 1/2" belt fits in the pulley compared to the ware marks from the old belt. Fits in the engine pulley the same way which fixed the belt popping off issue also. When I set the idler arm, I pushed the deck forward and tied the arm in place with a coat hanger.  I'll finish the deck adjustments for the engagement arm later. I just wanted the grass cut so I can move on to the next project. I think I figured out why the engine is smoking, should be fine the next time I cut the grass. Well, I went looking for my diesel fuel I use for cleaning parts, it's missing. I keep the diesel in the same kind of container as the regular gas. I thought I topped off the tank with gas, guess not. Explains the smell of the exhaust though. Evidently, I had about a 50/50 mix of gas and diesel in the tank, LOL. Explains the smoke too. Evidently I was rollin some coal too. The thing wouldn't idle either after I figured it out but I usually just use half and full throttle all the time because with the deck not shutting off would kill the motor anyways. I noticed it wouldn't idle after the deck belt popped off and figured the carb just needed cleaned. So, when I got the deck working, I cut the grass and just rode it around the yard a bit till I ran the gas dry. There is not one uncut blade of grass standing in my yards, LOL. | |

|   | | AllisKidD21

Moderator

2020 Build-Off Entrant

2020 Build-Off Entrant

1st Place Build-Off 2019

1st Place Build-Off Winner 2019

Age : 25

Join date : 2016-07-10

Points : 8378

Posts : 5190

Location : Ontario Canada

|  Subject: Re: Vari drive with 5 speed transaxle Subject: Re: Vari drive with 5 speed transaxle  August 11th 2019, 11:15 pm August 11th 2019, 11:15 pm | |

| Sounds like it was a pretty successful day!  "This'll either wake you up or put you to sleep forever!"- Red Green "Whatever you do you should do right, even if it's something wrong." - Hank Hill - MTD Off-Road Build

- Ford LT 110 Off-Road Build

- Craftsman GT 6000 Off-Road Build

- Sears LT11 Rat Rod Build *2019 Build-Off Winner!* Garden Tractor Collection: Allis B-110 x2, 710, 716, & 410 - Wheel Horse 655, 953 & 500 Special - Case 444 - Bolens Versamatic, G10 & 1668 Diesel Swapped - Cub 106, 124 & 1000/149 Frankentractor - Ford 120, LGT 125 & 145 - White 1650 Yard Boss - Moto Mower 710-100 | |

|   | | prancstaman

Veteran Member

Join date : 2015-02-02

Points : 4887

Posts : 1412

Location : Cleveland,Ohio

| |   | | Sponsored content

| |   | | | | Vari drive with 5 speed transaxle |  |

|

Similar topics |  |

|

| | Permissions in this forum: | You cannot reply to topics in this forum

| |

| |

| | Who is online? | In total there are 32 users online :: 0 Registered, 0 Hidden and 32 Guests

None

Most users ever online was 412 on January 7th 2023, 7:59 am

|

|

Later

Later