| | Rich's Tools and Projects |  |

|

+2AllisKidD21 RichieRichOverdrive 6 posters |

| Author | Message |

|---|

RichieRichOverdrive

Moderator

2018 Build-Off Entrant

2018 Build-Off Entrant

2024 Build-Off Entrant

2024 Build-Off Entrant

Age : 21

Join date : 2016-10-29

Points : 6612

Posts : 3634

Location : Lewisburg, KY

|  Subject: Rich's Tools and Projects Subject: Rich's Tools and Projects  March 25th 2020, 2:16 am March 25th 2020, 2:16 am | |

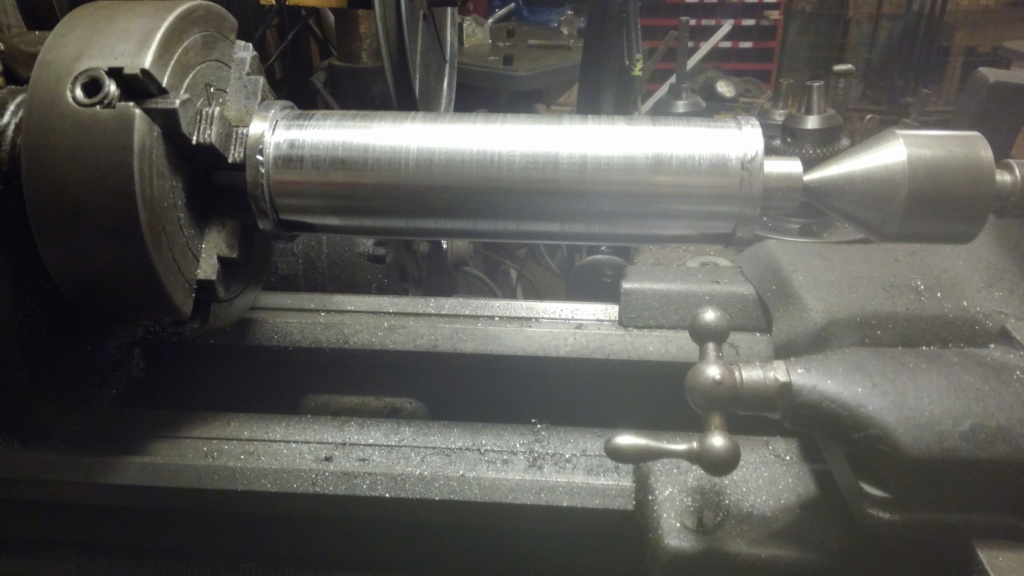

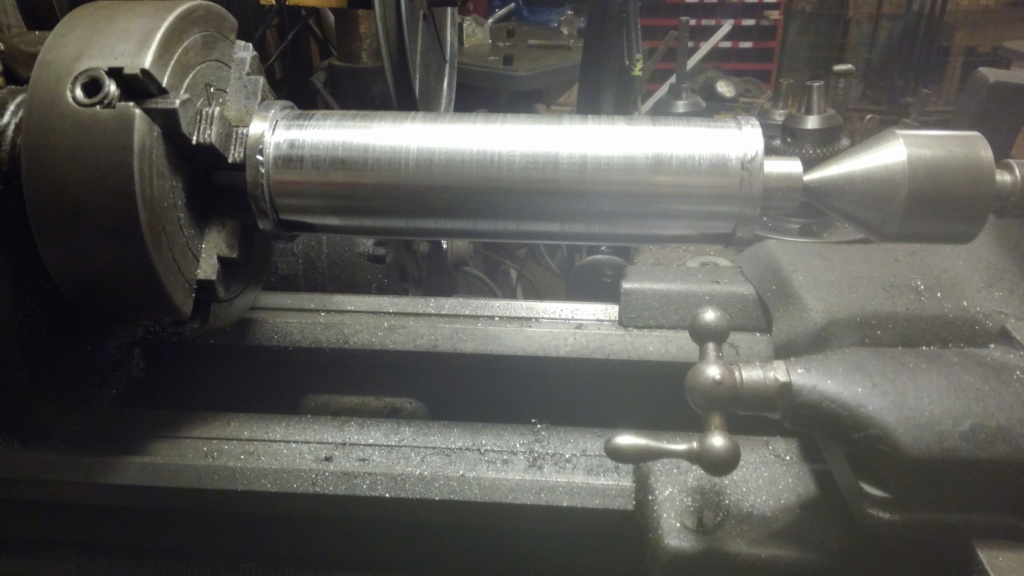

| Started on the rollers or drivers or drums, whatever you them for the belt grinder today. I've got to whittle 3 more ends out of sprockets to put in the pipe i have. Once i have both ends in a tube I'll weld it and then put it on a shaft in a lathe and turn the whole thing true. There's a lot of extra meat in this pipe so i have plenty of room for that.  | |

|

| |

RichieRichOverdrive

Moderator

2018 Build-Off Entrant

2018 Build-Off Entrant

2024 Build-Off Entrant

2024 Build-Off Entrant

Age : 21

Join date : 2016-10-29

Points : 6612

Posts : 3634

Location : Lewisburg, KY

|  Subject: Re: Rich's Tools and Projects Subject: Re: Rich's Tools and Projects  March 27th 2020, 12:03 am March 27th 2020, 12:03 am | |

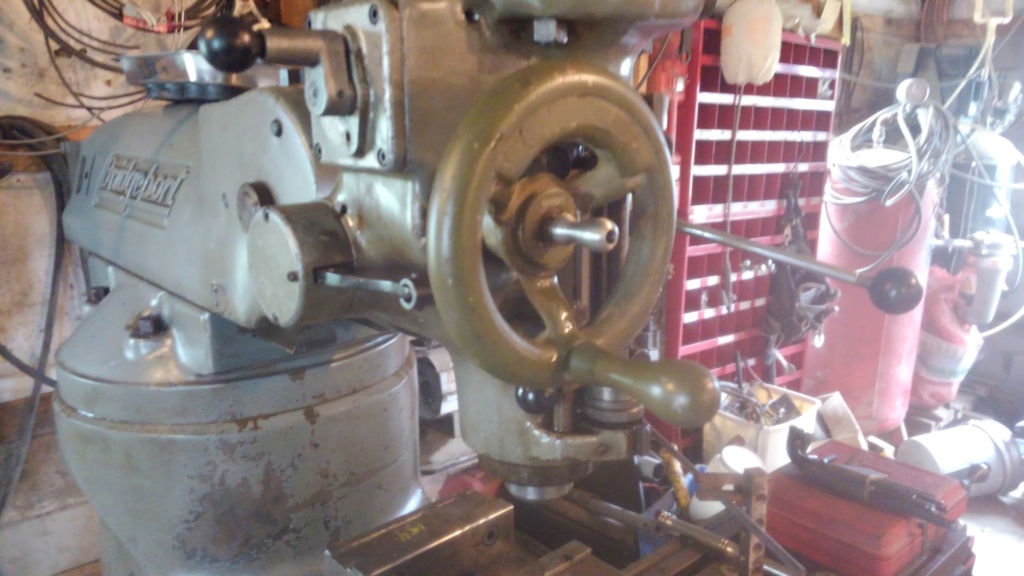

| So i got tired of the belt on my lathe slipping. I made a tensioner to help with heavy cuts.  | |

|

| |

AllisKidD21

Moderator

2020 Build-Off Entrant

2020 Build-Off Entrant

1st Place Build-Off 2019

1st Place Build-Off Winner 2019

Age : 25

Join date : 2016-07-10

Points : 8384

Posts : 5190

Location : Ontario Canada

|  Subject: Re: Rich's Tools and Projects Subject: Re: Rich's Tools and Projects  March 27th 2020, 8:44 am March 27th 2020, 8:44 am | |

| I'm starting to get the slightest impression that Rich has a lathe..   "This'll either wake you up or put you to sleep forever!"- Red Green "Whatever you do you should do right, even if it's something wrong." - Hank Hill - MTD Off-Road Build

- Ford LT 110 Off-Road Build

- Craftsman GT 6000 Off-Road Build

- Sears LT11 Rat Rod Build *2019 Build-Off Winner!* Garden Tractor Collection: Allis B-110 x2, 710, 716, & 410 - Wheel Horse 655, 953 & 500 Special - Case 444 - Bolens Versamatic, G10 & 1668 Diesel Swapped - Cub 106, 124 & 1000/149 Frankentractor - Ford 120, LGT 125 & 145 - White 1650 Yard Boss - Moto Mower 710-100 | |

|

| |

CraftsmanQuad19

Veteran Member

2018 Build-Off Entrant

2018 Build-Off Entrant

2019 Build-Off Finalist

2019 Build-Off Finalist

Age : 23

Join date : 2016-04-12

Points : 5756

Posts : 2623

Location : Indiana

| |

| |

RichieRichOverdrive

Moderator

2018 Build-Off Entrant

2018 Build-Off Entrant

2024 Build-Off Entrant

2024 Build-Off Entrant

Age : 21

Join date : 2016-10-29

Points : 6612

Posts : 3634

Location : Lewisburg, KY

|  Subject: Re: Rich's Tools and Projects Subject: Re: Rich's Tools and Projects  March 27th 2020, 6:16 pm March 27th 2020, 6:16 pm | |

| This thing has somehow diverted my attention from mowers but gotten me in the shop a lot more. Not entirely a bad thing haha. | |

|

| |

RichieRichOverdrive

Moderator

2018 Build-Off Entrant

2018 Build-Off Entrant

2024 Build-Off Entrant

2024 Build-Off Entrant

Age : 21

Join date : 2016-10-29

Points : 6612

Posts : 3634

Location : Lewisburg, KY

|  Subject: Re: Rich's Tools and Projects Subject: Re: Rich's Tools and Projects  March 28th 2020, 1:30 am March 28th 2020, 1:30 am | |

| Got both of the drivers turned for the belt grinder, finally starting to size things up. Cut a board to hold the drivers apart. Center to center i think it's 26" or 27", it was bigger than my 24" starret rule. It's turning out bigger than i thought, lol.  | |

|

| |

CraftsmanQuad19

Veteran Member

2018 Build-Off Entrant

2018 Build-Off Entrant

2019 Build-Off Finalist

2019 Build-Off Finalist

Age : 23

Join date : 2016-04-12

Points : 5756

Posts : 2623

Location : Indiana

|  Subject: Re: Rich's Tools and Projects Subject: Re: Rich's Tools and Projects  March 28th 2020, 1:53 am March 28th 2020, 1:53 am | |

| What if you make the bracket that holds the drums farther apart than you need, and mount one drum on a spring that pulls towards that bracket so it acts as a tensioner | |

|

| |

RichieRichOverdrive

Moderator

2018 Build-Off Entrant

2018 Build-Off Entrant

2024 Build-Off Entrant

2024 Build-Off Entrant

Age : 21

Join date : 2016-10-29

Points : 6612

Posts : 3634

Location : Lewisburg, KY

| |

| |

prancstaman

Veteran Member

Join date : 2015-02-02

Points : 4893

Posts : 1412

Location : Cleveland,Ohio

|  Subject: Re: Rich's Tools and Projects Subject: Re: Rich's Tools and Projects  March 28th 2020, 11:28 pm March 28th 2020, 11:28 pm | |

| I been working pretty steady since what I make is auto parts for speed shops. If the shut down lasts longer, more people will be layed off and I might be in that group of layoffs. Several people have been layed off already, where I work at. I was hoping to get layed off, I could use a vacation but I don't want to be either. Just been staying busy and distant from people as per the government advised. Got a little done on my project. That's about it for me. @RichieRichOverdrive You will need a way to adjust for tracking on the tensioner side of things. Would be good to be able to adjust the tension on each side of the roller independently. With the rollers being flat across, the belt will want to wonder side to side. The end caps you have on there will just tear up the belt when it hits them. It would also help to put an inch long bevel on both ends that extend under the belt of each roller, this will help with tracking of the belt. I actually build and fix the industrial versions of a belt sander at my job. | |

|

| |

RichieRichOverdrive

Moderator

2018 Build-Off Entrant

2018 Build-Off Entrant

2024 Build-Off Entrant

2024 Build-Off Entrant

Age : 21

Join date : 2016-10-29

Points : 6612

Posts : 3634

Location : Lewisburg, KY

|  Subject: Re: Rich's Tools and Projects Subject: Re: Rich's Tools and Projects  March 28th 2020, 11:42 pm March 28th 2020, 11:42 pm | |

| The bearings I have will gyrate in the housings to account for misalignment. I'm planning on aligning it off of that and a slot for the bearing and shaft to move in. I like your bevel idea, i may just do that. What kind of bevel are we talking, 5 or 10 degrees? Come to think of it, aren't flat belt pulleys rounded to keep the belt on? That would make sense in this application. | |

|

| |

prancstaman

Veteran Member

Join date : 2015-02-02

Points : 4893

Posts : 1412

Location : Cleveland,Ohio

|  Subject: Re: Rich's Tools and Projects Subject: Re: Rich's Tools and Projects  March 29th 2020, 9:03 am March 29th 2020, 9:03 am | |

| @RichieRichOverdrive Oh yah, I see on the gyrate in the housing thing, would be handy to make it adjustable while the machine is running. For the bevels, it's never a drastic angle that I see, I would say 5 degrees or less. On a polishing lathe setup (a bigger version of yours) the wheel that you do the grinding on can be flat with no bevel but the edges are rounded to prevent cutting into the belt and the belt always lays over the edge of the wheel. Meaning the belt is always wider then the wheel that you are grinding on. Oh, a little tidbit of info you can use, idler tension should be kept under 40 lbs. of pressure or you wear out the bearings fast and blow them. Would eventually blow the belt too, sounds like a shotgun, LOL. | |

|

| |

RichieRichOverdrive

Moderator

2018 Build-Off Entrant

2018 Build-Off Entrant

2024 Build-Off Entrant

2024 Build-Off Entrant

Age : 21

Join date : 2016-10-29

Points : 6612

Posts : 3634

Location : Lewisburg, KY

|  Subject: Re: Rich's Tools and Projects Subject: Re: Rich's Tools and Projects  March 29th 2020, 2:52 pm March 29th 2020, 2:52 pm | |

| I started putting on a bevel last night, 2° and 1¼" in from the sides. Seems right. | |

|

| |

prancstaman

Veteran Member

Join date : 2015-02-02

Points : 4893

Posts : 1412

Location : Cleveland,Ohio

|  Subject: Riche's Tools and Projects Subject: Riche's Tools and Projects  March 29th 2020, 7:49 pm March 29th 2020, 7:49 pm | |

| - RichieRichOverdrive wrote:

- I started putting on a bevel last night, 2° and 1¼" in from the sides. Seems right.

Should be good. You will notice the belt will kinda take shape of the roller when tight, is a good thing. When running, the belt always wants to run on the high spot of the wheel which you are controlling with the bevels on the ends. We run the idlers till they blow, LOL. The belt wears the center down which makes it a smaller diameter, so the belt kicks to the sides when adjusting it in. A trick to fix this is putting masking take on the center of the wheel to temporarily build it back up so the belt tracks right in the center again. Lasts till we get another idler wheel, LOL. | |

|

| |

RichieRichOverdrive

Moderator

2018 Build-Off Entrant

2018 Build-Off Entrant

2024 Build-Off Entrant

2024 Build-Off Entrant

Age : 21

Join date : 2016-10-29

Points : 6612

Posts : 3634

Location : Lewisburg, KY

|  Subject: Re: Rich's Tools and Projects Subject: Re: Rich's Tools and Projects  March 31st 2020, 5:54 pm March 31st 2020, 5:54 pm | |

| In the process of making a material guide for my bandsaw, i broke the blade on it.  Moderately disgruntled, i finished it with a hacksaw. | |

|

| |

RichieRichOverdrive

Moderator

2018 Build-Off Entrant

2018 Build-Off Entrant

2024 Build-Off Entrant

2024 Build-Off Entrant

Age : 21

Join date : 2016-10-29

Points : 6612

Posts : 3634

Location : Lewisburg, KY

|  Subject: Re: Rich's Tools and Projects Subject: Re: Rich's Tools and Projects  April 1st 2020, 12:04 pm April 1st 2020, 12:04 pm | |

| Finished off the other roller today.  I think me welding the hubs hardened them. HSS won't touch them now. | |

|

| |

RichieRichOverdrive

Moderator

2018 Build-Off Entrant

2018 Build-Off Entrant

2024 Build-Off Entrant

2024 Build-Off Entrant

Age : 21

Join date : 2016-10-29

Points : 6612

Posts : 3634

Location : Lewisburg, KY

| |

| |

TheBeal

Veteran Member

Age : 29

Join date : 2013-06-06

Points : 5510

Posts : 1398

Location : Central PA

| |

| |

CosmicArkie

New Member

Join date : 2019-02-24

Points : 1921

Posts : 22

Location : Texas

|  Subject: Re: Rich's Tools and Projects Subject: Re: Rich's Tools and Projects  April 4th 2020, 10:59 am April 4th 2020, 10:59 am | |

| Rich, as far as the cold blueing goes, I've found that a little heat is a good thing - kinda opens up the pores of the metal. Warming with a heat gun is sufficient to get the blueing nicely evened out.

JMHO YMMV | |

|

| |

RichieRichOverdrive

Moderator

2018 Build-Off Entrant

2018 Build-Off Entrant

2024 Build-Off Entrant

2024 Build-Off Entrant

Age : 21

Join date : 2016-10-29

Points : 6612

Posts : 3634

Location : Lewisburg, KY

|  Subject: Re: Rich's Tools and Projects Subject: Re: Rich's Tools and Projects  April 4th 2020, 12:23 pm April 4th 2020, 12:23 pm | |

| I couldn't find any alcohol to properly clean it, so that wouldn't really have made that much difference. I was out in the sun on my little shop patio though. So that probably did help. Thanks for the tip.

| |

|

| |

CosmicArkie

New Member

Join date : 2019-02-24

Points : 1921

Posts : 22

Location : Texas

| |

| |

RichieRichOverdrive

Moderator

2018 Build-Off Entrant

2018 Build-Off Entrant

2024 Build-Off Entrant

2024 Build-Off Entrant

Age : 21

Join date : 2016-10-29

Points : 6612

Posts : 3634

Location : Lewisburg, KY

|  Subject: Re: Rich's Tools and Projects Subject: Re: Rich's Tools and Projects  April 4th 2020, 12:37 pm April 4th 2020, 12:37 pm | |

| I did hit it with some carb cleaner. I'm pretty conservative with that stuff though, especially now. | |

|

| |

RichieRichOverdrive

Moderator

2018 Build-Off Entrant

2018 Build-Off Entrant

2024 Build-Off Entrant

2024 Build-Off Entrant

Age : 21

Join date : 2016-10-29

Points : 6612

Posts : 3634

Location : Lewisburg, KY

|  Subject: Re: Rich's Tools and Projects Subject: Re: Rich's Tools and Projects  April 8th 2020, 2:27 am April 8th 2020, 2:27 am | |

| I finally made myself a bead breaker thingy. Wasnt really the plan when i got up today but the gt6k's rims have a big beadlock in the rim that made it a pain to get the tire over the bead. I have a big metal plate I'll drill and tap holes to bolt it to, for now it's just clamped onto some c channel so i can get these tires finished up  | |

|

| |

RichieRichOverdrive

Moderator

2018 Build-Off Entrant

2018 Build-Off Entrant

2024 Build-Off Entrant

2024 Build-Off Entrant

Age : 21

Join date : 2016-10-29

Points : 6612

Posts : 3634

Location : Lewisburg, KY

|  Subject: Re: Rich's Tools and Projects Subject: Re: Rich's Tools and Projects  May 23rd 2020, 2:47 am May 23rd 2020, 2:47 am | |

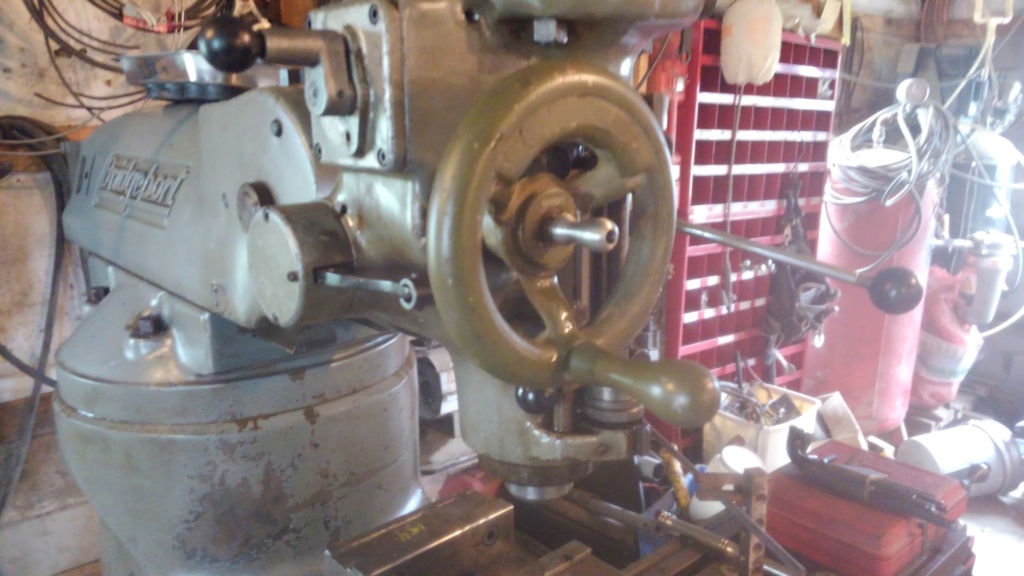

| So i got a bit of a graduation present...or a "sorry communist china entirely obliterated your senior year" present, however you will...  1974 vintage Bridgeport 1hp J head, 9x42 table, milling machine, with (of course non working) factory X axis powerfeed. Alright I've tried to upload more pictures and finish this post for 15 minutes now but every time I try to upload a picture the website tries to reload and says something like "unable to perform previous operation due to low memory" Actually it worked for once, here's the vise i got with it. I believe it's a 6" Enco pull down vise judging by the bit of burgundy paint on it. It's currently being cleaned with electrolysis because it was rusty on the inside and felt crusty.  Here's an old army surplus handwheel that happened to fit the quill fine feed shaft nicely. Had to drill and ream a ⅛" hole and tap in a roll pin and it works nicely, even as it's total overkill. You can also see the knob i turned for the feed reverse selector.  As it turns out, the feed selector knob was really for nought as a bevel gear higher up in the quill feed drive is stripped. I can still use the handwheel for fine feed though.  These are the X and Y axis locks, neither came with a the original handle, and due to an optical scale option this machine the saddle was tapped for a traditional lock but didnt have one. The darker piece is the original, everything else i turned myself.  Got this one to upload without site crashing on like try 5 or 6. Lost count. The powerfeed has a 90v DC motor. I think there's a short in the windings from the motor getting oil in it and the oil burning off. When you run it it starts smoking almost immediately, but it's more of a burnt brush smell than a burnt conformal coating smell. The commutator bars get really hot especially in one spot. You guys are smarter than me on this stuff so it you have any insight on brushed DC motors please let me know.  That's about all the pictures i have for now, other stuff has gone on too, nothing major though. Machine vise and baking soda soup  | |

|

| |

prancstaman

Veteran Member

Join date : 2015-02-02

Points : 4893

Posts : 1412

Location : Cleveland,Ohio

|  Subject: Re: Rich's Tools and Projects Subject: Re: Rich's Tools and Projects  May 24th 2020, 12:24 am May 24th 2020, 12:24 am | |

| Nice Bridgeport. Got one at my job like that one. You can try drying out the armature with brake clean and blow it out, to see if it still shorts out. Use a multimeter to try testing it. Set for ohms and should be 0 resistance with both leads on computator where the brushes ride. Then full resistance or no contact from computator to shaft of armature. | |

|

| |

RichieRichOverdrive

Moderator

2018 Build-Off Entrant

2018 Build-Off Entrant

2024 Build-Off Entrant

2024 Build-Off Entrant

Age : 21

Join date : 2016-10-29

Points : 6612

Posts : 3634

Location : Lewisburg, KY

|  Subject: Re: Rich's Tools and Projects Subject: Re: Rich's Tools and Projects  May 24th 2020, 10:53 pm May 24th 2020, 10:53 pm | |

| I'm looking at getting it rewound and rebuilt. I'm afraid some solvent will hurt the conformal coating | |

|

| |

Sponsored content

| |

| |

| | Rich's Tools and Projects |  |

|