|

| | Doug's RER Snapper - "Zephyr" |  |

|

+7mr.modified TheBeal MatthewD RichieRichOverdrive Doc Sprocket AllisKidD21 Doug 11 posters | |

| Author | Message |

|---|

Doug

Site Owner

2014 Build-Off Entrant

2014 Build-Off Entrant

2017 Build-Off Entrant

2017 Build-Off Entrant

Age : 29

Join date : 2012-12-24

Points : 7750

Posts : 3044

Location : Lebanon County, PA

|  Subject: Doug's RER Snapper - "Zephyr" Subject: Doug's RER Snapper - "Zephyr"  May 19th 2017, 6:11 pm May 19th 2017, 6:11 pm | |

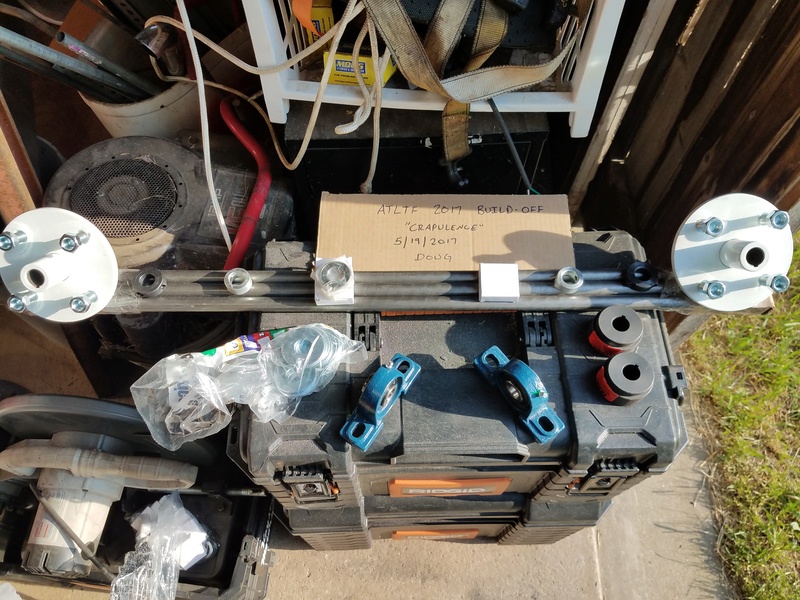

| Time to show who the true rear engine Snapper king is. Starting as a normal engineless Snapper RER, which I picked up from mr.modified, it's being completely stripped. From there, the rear frame will be modified to mount a standard transaxle and a V twin Briggs. Plans to add a heavy rear bumper with removable wheelie bar and possibly a winch. From there, the "frame" or tube will be extended and the seat possibly mounted to it. The front axle will be made from a golf cart axle and will utilize direct steering. Hand mounted throttle is planned, with brake and clutch being actuated by cable. If the driver seat is mounted to the tube, gear shifting will also need to be achieved by cable. It will be pushed by an MST206 using a doc locker and additional axle supports. Rear tires will be Kenda Bearclaws, unsure on front at the moment. Only 3 weeks till Haspin, will I make it?    Head Forum Administrator ** Chat Moderator ** Facebook Page AdminATLTF Facebook Page ** Chatbox ** How To Upload Pictures

_X_ FORUM ANNOUNCEMENTS _X_Have a question? Ask me! Type in "@Doug" in your post!

Your ATLTF Staff:

Administrators: @Doug, @MightyRaze, @"Doc Sprocket", @Stretch44875

Moderators: @TheRainbowBoxer, @AllisKidD21, @Brianator, @RichieRichOverdrive

| |

|   | | AllisKidD21

Moderator

2020 Build-Off Entrant

2020 Build-Off Entrant

1st Place Build-Off 2019

1st Place Build-Off Winner 2019

Age : 25

Join date : 2016-07-10

Points : 8558

Posts : 5190

Location : Ontario Canada

|  Subject: Re: Doug's RER Snapper - "Zephyr" Subject: Re: Doug's RER Snapper - "Zephyr"  May 19th 2017, 6:37 pm May 19th 2017, 6:37 pm | |

| Sounds cool Doug. Ya gonna keep the suspension on the golf kart axle and have it on this??  "This'll either wake you up or put you to sleep forever!"- Red Green "Whatever you do you should do right, even if it's something wrong." - Hank Hill - MTD Off-Road Build

- Ford LT 110 Off-Road Build

- Craftsman GT 6000 Off-Road Build

- Sears LT11 Rat Rod Build *2019 Build-Off Winner!* Garden Tractor Collection: Allis B-110 x2, 710, 716, & 410 - Wheel Horse 655, 953 & 500 Special - Case 444 - Bolens Versamatic, G10 & 1668 Diesel Swapped - Cub 106, 124 & 1000/149 Frankentractor - Ford 120, LGT 125 & 145 - White 1650 Yard Boss - Moto Mower 710-100 | |

|   | | Doc Sprocket

Site VIP

2018 Build-Off Entrant

2018 Build-Off Entrant

2021 Winner of Winners

2021 Winner of Winners

1st Place Build-Off 2016

1st Place Build-Off Winner 2016

Age : 51

Join date : 2013-04-21

Points : 7289

Posts : 2914

Location : Ontario Canada

|  Subject: Re: Doug's RER Snapper - "Zephyr" Subject: Re: Doug's RER Snapper - "Zephyr"  May 19th 2017, 6:55 pm May 19th 2017, 6:55 pm | |

| Uh-oh! Y'all remember what happened the LAST time an admin entered the Build-Off, right? Look out!  Good luck, Dougie! | |

|   | | Doug

Site Owner

2014 Build-Off Entrant

2014 Build-Off Entrant

2017 Build-Off Entrant

2017 Build-Off Entrant

Age : 29

Join date : 2012-12-24

Points : 7750

Posts : 3044

Location : Lebanon County, PA

|  Subject: Re: Doug's RER Snapper - "Zephyr" Subject: Re: Doug's RER Snapper - "Zephyr"  May 19th 2017, 8:48 pm May 19th 2017, 8:48 pm | |

| - AllisKidD21 wrote:

- Sounds cool Doug. Ya gonna keep the suspension on the golf kart axle and have it on this??

No, it'll pivot as the stock axle does. Just be much, much heavier. This thing is gonna pop wheelies like mad.  Head Forum Administrator ** Chat Moderator ** Facebook Page AdminATLTF Facebook Page ** Chatbox ** How To Upload Pictures

_X_ FORUM ANNOUNCEMENTS _X_Have a question? Ask me! Type in "@Doug" in your post!

Your ATLTF Staff:

Administrators: @Doug, @MightyRaze, @"Doc Sprocket", @Stretch44875

Moderators: @TheRainbowBoxer, @AllisKidD21, @Brianator, @RichieRichOverdrive

| |

|   | | AllisKidD21

Moderator

2020 Build-Off Entrant

2020 Build-Off Entrant

1st Place Build-Off 2019

1st Place Build-Off Winner 2019

Age : 25

Join date : 2016-07-10

Points : 8558

Posts : 5190

Location : Ontario Canada

|  Subject: Re: Doug's RER Snapper - "Zephyr" Subject: Re: Doug's RER Snapper - "Zephyr"  May 19th 2017, 8:57 pm May 19th 2017, 8:57 pm | |

| - Doug wrote:

- AllisKidD21 wrote:

- Sounds cool Doug. Ya gonna keep the suspension on the golf kart axle and have it on this??

No, it'll pivot as the stock axle does. Just be much, much heavier. This thing is gonna pop wheelies like mad. Oh ok, you had me excited for a minute! Hahaha, good thing you have "wheelie bar" on the list!  "This'll either wake you up or put you to sleep forever!"- Red Green "Whatever you do you should do right, even if it's something wrong." - Hank Hill - MTD Off-Road Build

- Ford LT 110 Off-Road Build

- Craftsman GT 6000 Off-Road Build

- Sears LT11 Rat Rod Build *2019 Build-Off Winner!* Garden Tractor Collection: Allis B-110 x2, 710, 716, & 410 - Wheel Horse 655, 953 & 500 Special - Case 444 - Bolens Versamatic, G10 & 1668 Diesel Swapped - Cub 106, 124 & 1000/149 Frankentractor - Ford 120, LGT 125 & 145 - White 1650 Yard Boss - Moto Mower 710-100 | |

|   | | RichieRichOverdrive

Moderator

2018 Build-Off Entrant

2018 Build-Off Entrant

2024 Build-Off Entrant

2024 Build-Off Entrant

Age : 22

Join date : 2016-10-29

Points : 7165

Posts : 3993

Location : Lewisburg, KY

|  Subject: Re: Doug's RER Snapper - "Zephyr" Subject: Re: Doug's RER Snapper - "Zephyr"  May 19th 2017, 11:26 pm May 19th 2017, 11:26 pm | |

| - Doc Sprocket wrote:

- Uh-oh! Y'all remember what happened the LAST time an admin entered the Build-Off, right? Look out!

Good luck, Dougie! I think that admin tried to burn down their garage  can't remember CHEESE AND RICE FACKLER A V TWIN? What pulleys you runnin?  Also keep in mind that you can't steer with the front end in the air. Better go to mickeys and bulk up so you can keep the front wheels on the ground!!!  | |

|   | | Doug

Site Owner

2014 Build-Off Entrant

2014 Build-Off Entrant

2017 Build-Off Entrant

2017 Build-Off Entrant

Age : 29

Join date : 2012-12-24

Points : 7750

Posts : 3044

Location : Lebanon County, PA

| |   | | Doug

Site Owner

2014 Build-Off Entrant

2014 Build-Off Entrant

2017 Build-Off Entrant

2017 Build-Off Entrant

Age : 29

Join date : 2012-12-24

Points : 7750

Posts : 3044

Location : Lebanon County, PA

| |   | | AllisKidD21

Moderator

2020 Build-Off Entrant

2020 Build-Off Entrant

1st Place Build-Off 2019

1st Place Build-Off Winner 2019

Age : 25

Join date : 2016-07-10

Points : 8558

Posts : 5190

Location : Ontario Canada

|  Subject: Re: Doug's RER Snapper - "Zephyr" Subject: Re: Doug's RER Snapper - "Zephyr"  May 20th 2017, 9:50 am May 20th 2017, 9:50 am | |

| Transaxle mounts look great! I think those pulleys are pretty well aligned, I don't see the problem? Hahaha!  "This'll either wake you up or put you to sleep forever!"- Red Green "Whatever you do you should do right, even if it's something wrong." - Hank Hill - MTD Off-Road Build

- Ford LT 110 Off-Road Build

- Craftsman GT 6000 Off-Road Build

- Sears LT11 Rat Rod Build *2019 Build-Off Winner!* Garden Tractor Collection: Allis B-110 x2, 710, 716, & 410 - Wheel Horse 655, 953 & 500 Special - Case 444 - Bolens Versamatic, G10 & 1668 Diesel Swapped - Cub 106, 124 & 1000/149 Frankentractor - Ford 120, LGT 125 & 145 - White 1650 Yard Boss - Moto Mower 710-100 | |

|   | | MatthewD

Veteran Member

2015 Build-Off Entrant

2015 Build-Off Entrant

2016 Build-Off Entrant

2016 Build-Off Entrant

Age : 23

Join date : 2014-11-16

Points : 5724

Posts : 1993

Location : Northern Ireland

| |   | | TheBeal

Veteran Member

Age : 30

Join date : 2013-06-06

Points : 5688

Posts : 1402

Location : Central PA

| |   | | MatthewD

Veteran Member

2015 Build-Off Entrant

2015 Build-Off Entrant

2016 Build-Off Entrant

2016 Build-Off Entrant

Age : 23

Join date : 2014-11-16

Points : 5724

Posts : 1993

Location : Northern Ireland

| |   | | Doug

Site Owner

2014 Build-Off Entrant

2014 Build-Off Entrant

2017 Build-Off Entrant

2017 Build-Off Entrant

Age : 29

Join date : 2012-12-24

Points : 7750

Posts : 3044

Location : Lebanon County, PA

| |   | | mr.modified

Veteran Member

2015 Build-Off Top 3 Winner

2015 Build-Off Top 3 Winner

2016 Build-Off Top 3 Winner

2016 Build-Off Top 3 Winner

2018 Build-Off Finalist

2018 Build-Off Finalist

2022 Build-Off Entrant

2022 Build-Off Entrant

1st Place Build-Off 2014

1st Place Build-Off Winner 2014

2023 Build-Off Entrant

2023 Build-Off Entrant

Age : 34

Join date : 2013-11-02

Points : 7135

Posts : 2907

Location : New Jersey USA

| |   | | Doug

Site Owner

2014 Build-Off Entrant

2014 Build-Off Entrant

2017 Build-Off Entrant

2017 Build-Off Entrant

Age : 29

Join date : 2012-12-24

Points : 7750

Posts : 3044

Location : Lebanon County, PA

|  Subject: Re: Doug's RER Snapper - "Zephyr" Subject: Re: Doug's RER Snapper - "Zephyr"  May 24th 2017, 10:56 pm May 24th 2017, 10:56 pm | |

| So not much has happened while I was waiting for my jackshaft bearings. Well, they arrived today... and two were wrong. I had ordered a pair of flange and a pair of normal pillow blocks so I could do whatever, but when I opened the box today there were 4 pillow blocks. I could do all pillows, but would rather not. I contacted the seller and am waiting on a response. I did get the pulleys all welded together... mostly. One of the 5/8 hubs I got was actually 11/16, so I had to return it back to TSC and run to True Value to get the proper hub since TSC cant stock anything. Also got like a 2 or 3" flat idler for the clutch. But anyways, pullies all welded, and the three I had gotten before my hub dilemma got paint. Decided on yellow, since its what I had, but should look neat underneath and brighten up the underside.   Head Forum Administrator ** Chat Moderator ** Facebook Page AdminATLTF Facebook Page ** Chatbox ** How To Upload Pictures

_X_ FORUM ANNOUNCEMENTS _X_Have a question? Ask me! Type in "@Doug" in your post!

Your ATLTF Staff:

Administrators: @Doug, @MightyRaze, @"Doc Sprocket", @Stretch44875

Moderators: @TheRainbowBoxer, @AllisKidD21, @Brianator, @RichieRichOverdrive

| |

|   | | CraftsmanQuad19

Veteran Member

2018 Build-Off Entrant

2018 Build-Off Entrant

2019 Build-Off Finalist

2019 Build-Off Finalist

Age : 24

Join date : 2016-04-12

Points : 5946

Posts : 2639

Location : Indiana

|  Subject: Re: Doug's RER Snapper - "Zephyr" Subject: Re: Doug's RER Snapper - "Zephyr"  May 25th 2017, 8:02 am May 25th 2017, 8:02 am | |

| What if you mount the jackshaft so it can move, and use that as your clutch? That way you don't need any idlers. | |

|   | | mr.modified

Veteran Member

2015 Build-Off Top 3 Winner

2015 Build-Off Top 3 Winner

2016 Build-Off Top 3 Winner

2016 Build-Off Top 3 Winner

2018 Build-Off Finalist

2018 Build-Off Finalist

2022 Build-Off Entrant

2022 Build-Off Entrant

1st Place Build-Off 2014

1st Place Build-Off Winner 2014

2023 Build-Off Entrant

2023 Build-Off Entrant

Age : 34

Join date : 2013-11-02

Points : 7135

Posts : 2907

Location : New Jersey USA

|  Subject: Re: Doug's RER Snapper - "Zephyr" Subject: Re: Doug's RER Snapper - "Zephyr"  May 25th 2017, 12:36 pm May 25th 2017, 12:36 pm | |

| - Doug wrote:

- since TSC cant stock anything.

This is true, same with the one near me. How hard is it to re-order things and put them on the shelf. Weeks go by and they are still out of stuff. MSCdirect.com has cheap bearings, not sure who you buy from, but there's a bunch of options on there for anyone who wants to look. Anyway, If he made the jackshaft movable, then both belts would slacken/tighten, May work better as far as disengaging, because both belts would be loose at the same time, but It might mean one belt is tighter than the other when the clutch is released, depending on how they both stretch. I'm thinking that might mean belt slipping issues. | |

|   | | CraftsmanQuad19

Veteran Member

2018 Build-Off Entrant

2018 Build-Off Entrant

2019 Build-Off Finalist

2019 Build-Off Finalist

Age : 24

Join date : 2016-04-12

Points : 5946

Posts : 2639

Location : Indiana

|  Subject: Re: Doug's RER Snapper - "Zephyr" Subject: Re: Doug's RER Snapper - "Zephyr"  May 25th 2017, 1:22 pm May 25th 2017, 1:22 pm | |

| With belts that short, would the difference in stretch be that much? Not trying to start an argument or anything, I'm just genuinely curious. I thought since both belts disengaged it would disengage very smoothly and could sit in gear with the clutch in and won't want to creep forward. | |

|   | | mr.modified

Veteran Member

2015 Build-Off Top 3 Winner

2015 Build-Off Top 3 Winner

2016 Build-Off Top 3 Winner

2016 Build-Off Top 3 Winner

2018 Build-Off Finalist

2018 Build-Off Finalist

2022 Build-Off Entrant

2022 Build-Off Entrant

1st Place Build-Off 2014

1st Place Build-Off Winner 2014

2023 Build-Off Entrant

2023 Build-Off Entrant

Age : 34

Join date : 2013-11-02

Points : 7135

Posts : 2907

Location : New Jersey USA

|  Subject: Re: Doug's RER Snapper - "Zephyr" Subject: Re: Doug's RER Snapper - "Zephyr"  May 25th 2017, 8:30 pm May 25th 2017, 8:30 pm | |

| I don't know, maybe they would both even out after a bit. Yeah that's what I mean too about not wanting to creep forward or drag. It would be good for that I think.

Edit: I was just thinking, if the pulleys on the engine and transaxle are going to be the same size, and both on the jackshaft are the same, then using the jackshaft as a clutch wouldn't be so bad, it would be the same as a dual belt drive on something. But if you had different size pulleys for changing ratio, then wouldn't it have two different belt sizes? And then maybe one wouldn't be able to line up. Or one would be tight before the other one right? Guess the stretching thing wouldn't be an issue as long as they both tighten up at the same time. But I think maybe your right, might be a good idea to make it like that. | |

|   | | RichieRichOverdrive

Moderator

2018 Build-Off Entrant

2018 Build-Off Entrant

2024 Build-Off Entrant

2024 Build-Off Entrant

Age : 22

Join date : 2016-10-29

Points : 7165

Posts : 3993

Location : Lewisburg, KY

|  Subject: Re: Doug's RER Snapper - "Zephyr" Subject: Re: Doug's RER Snapper - "Zephyr"  May 25th 2017, 10:21 pm May 25th 2017, 10:21 pm | |

| - mr.modified wrote:

- I don't know, maybe they would both even out after a bit. Yeah that's what I mean too about not wanting to creep forward or drag. It would be good for that I think.

Edit: I was just thinking, if the pulleys on the engine and transaxle are going to be the same size, and both on the jackshaft are the same, then using the jackshaft as a clutch wouldn't be so bad, it would be the same as a dual belt drive on something. But if you had different size pulleys for changing ratio, then wouldn't it have two different belt sizes? And then maybe one wouldn't be able to line up. Or one would be tight before the other one right? Guess the stretching thing wouldn't be an issue as long as they both tighten up at the same time. But I think maybe your right, might be a good idea to make it like that. If your belt sizes are correct they should engage at the same time. But that's in the perfect world where belt wrappage doesn't come into effect. In (my) theory, if for example you have a pair of big pulleys on top, and a pair of small pulleys on bottom, the bigger pulleys would engage first due to the extra friction from more surface area and then the bottom pulleys can slip to the extent that the belt wears faster on the bottom while the top doesn't, so you'll either have to have your jackshaft somehow adjustable and therefore misaligned, or you would have to have some sort of adjustment on whichever belt wears faster. I think it'd just be easier to do a clutch on the bottom so then the transaxle doesn't have all that rotating mass so you can shift (something i believe you are familiar with on the simplicity). Then again, you can argue that you'd want the clutch on the top to ease pressure on the starter (when starting).  | |

|   | | Doug

Site Owner

2014 Build-Off Entrant

2014 Build-Off Entrant

2017 Build-Off Entrant

2017 Build-Off Entrant

Age : 29

Join date : 2012-12-24

Points : 7750

Posts : 3044

Location : Lebanon County, PA

|  Subject: Re: Doug's RER Snapper - "Zephyr" Subject: Re: Doug's RER Snapper - "Zephyr"  May 25th 2017, 11:03 pm May 25th 2017, 11:03 pm | |

| With my pulleys (2x 5" and 2x 4", it would be doable. I actually considered doing that, but figured it would probably be bulky. I figure the clutch arm will be mounted onto the bottom jackshaft/ frame support, and it will be operated by cable. Should be ok... hopefully.  Head Forum Administrator ** Chat Moderator ** Facebook Page AdminATLTF Facebook Page ** Chatbox ** How To Upload Pictures

_X_ FORUM ANNOUNCEMENTS _X_Have a question? Ask me! Type in "@Doug" in your post!

Your ATLTF Staff:

Administrators: @Doug, @MightyRaze, @"Doc Sprocket", @Stretch44875

Moderators: @TheRainbowBoxer, @AllisKidD21, @Brianator, @RichieRichOverdrive

| |

|   | | Stretch44875

Administrator

Age : 49

Join date : 2012-04-05

Points : 5672

Posts : 959

Location : Mansfield, Ohio

|  Subject: Re: Doug's RER Snapper - "Zephyr" Subject: Re: Doug's RER Snapper - "Zephyr"  May 26th 2017, 8:43 am May 26th 2017, 8:43 am | |

| I had a double pulley deck spindle that worked for a jack shaft. One belt was clutch, other has a spring holding idler in, so it is always tight. | |

|   | | TheBeal

Veteran Member

Age : 30

Join date : 2013-06-06

Points : 5688

Posts : 1402

Location : Central PA

| |   | | Doug

Site Owner

2014 Build-Off Entrant

2014 Build-Off Entrant

2017 Build-Off Entrant

2017 Build-Off Entrant

Age : 29

Join date : 2012-12-24

Points : 7750

Posts : 3044

Location : Lebanon County, PA

|  Subject: Re: Doug's RER Snapper - "Zephyr" Subject: Re: Doug's RER Snapper - "Zephyr"  May 26th 2017, 8:40 pm May 26th 2017, 8:40 pm | |

| - Stretch44875 wrote:

- I had a double pulley deck spindle that worked for a jack shaft. One belt was clutch, other has a spring holding idler in, so it is always tight.

Yeah I remember that, was kind of sketchy looking lol. You shouldbring it as a spare, ill slap one of my transmissions in it. :^) - TheBeal wrote:

- Doug wrote:

- 1v1 me at Haspin bro

Id hate to show you up...  Its on like donkey kong.  Head Forum Administrator ** Chat Moderator ** Facebook Page AdminATLTF Facebook Page ** Chatbox ** How To Upload Pictures

_X_ FORUM ANNOUNCEMENTS _X_Have a question? Ask me! Type in "@Doug" in your post!

Your ATLTF Staff:

Administrators: @Doug, @MightyRaze, @"Doc Sprocket", @Stretch44875

Moderators: @TheRainbowBoxer, @AllisKidD21, @Brianator, @RichieRichOverdrive

| |

|   | | TheBeal

Veteran Member

Age : 30

Join date : 2013-06-06

Points : 5688

Posts : 1402

Location : Central PA

| |   | | Sponsored content

| |   | | | | Doug's RER Snapper - "Zephyr" |  |

|

Similar topics |  |

|

| | Permissions in this forum: | You cannot reply to topics in this forum

| |

| |

| | Who is online? | In total there are 9 users online :: 0 Registered, 0 Hidden and 9 Guests

None

Most users ever online was 412 on January 7th 2023, 7:59 am

|

|